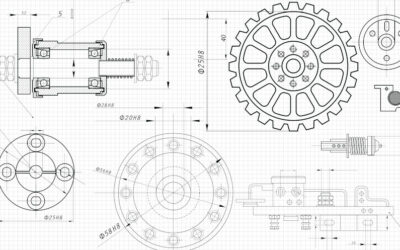

Design tolerances are an essential aspect of quality assurance and quality control. Engineers and quality specialists know that manufactured parts rarely measure exactly the same as the design dimension. In machining, this could mean slightly too little or too much...

Blog

What is Tensile Strength, and Why Does it Matter to Engineers?

Tensile strength is a critical property that engineers and materials specialists must consider when designing and selecting materials for their applications. It refers to the maximum amount of stress a material can withstand before breaking or deforming under tension....

3 Tips to Help You Design for Wear Resistance and High Wear Applications

In our last article, we talked about wear resistance, and for many products, getting “worn out” is a key factor in determining the item’s service lifetime. That could be decades or only hours depending on the application and how aggressive the wear conditions are....

What Is Wear Resistance and How Do You Prevent Wear in Your Products?

Wear is a powerful force that causes materials to deteriorate over time. It affects everything from kitchen knives and shoe insoles to the bucket teeth on heavy mining equipment. In fact, whenever one material’s surface rubs against another, both materials could be...

What is Reverse Engineering, and When do You Apply It?

In order to innovate and improve a technology or process, designers must have an in-depth knowledge of existing systems, either because they had a hand in the design of the originals or because they applied reverse engineering principles. Reverse engineering as a...

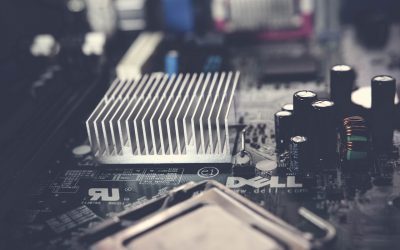

The Basics of Heat Sinks: How Do They Work?

You don’t need to be an MIT graduate to know that electronic devices and machines generate heat when operating. When left unsupervised, this situation can quickly lead to the device overheating, causing it to malfunction. Then, unless you react quickly enough, this...

Snap-fit Design 101: Basics, Types, and Best Practices for Snap Fit Joints

Have you recently come up with a product idea, or do you need to manufacture parts with special requirements? If so, you’re likely looking to create high-quality parts while reducing manufacturing costs and improving aesthetics and ease of assembly. One essential...

What is Diamond-like Carbon Coating? Here is What Product Designers Must Know

Are you a product designer looking to create parts or components that will make contact with other parts or assemblies, or do you plan to create products that will be exposed to harsh chemicals or environments? If so, you must choose a material with high wear and...

Springs 101: Understanding the Basics and Types of Springs

Springs are mechanical components that elastically absorb applied loads. By “elastically,” we mean that these springs will return to their original position once you remove the applied load. This makes them useful in applications that demand energy storage or...

Back to the Basics: Types of Fasteners and How to Choose Them

Modern machinery usually comprises several parts assembled to make a fully-operational product. However, these pieces of machinery usually generate huge forces and experience vibrations large enough to disassemble the parts and cause failure. Fasteners are essential...