Die Casting

Aluminum and Zinc Die Casting Services in China

Top-notch China Die Casting Supplier

Are you looking for a reliable and quick-turn provider of die casting services? You’ve come to the right place!

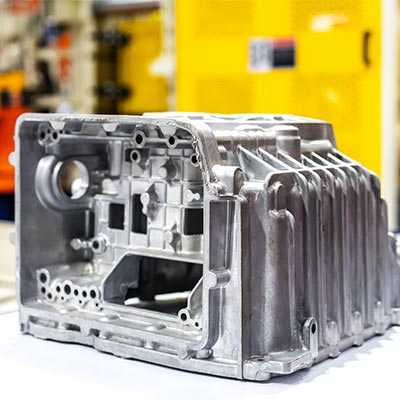

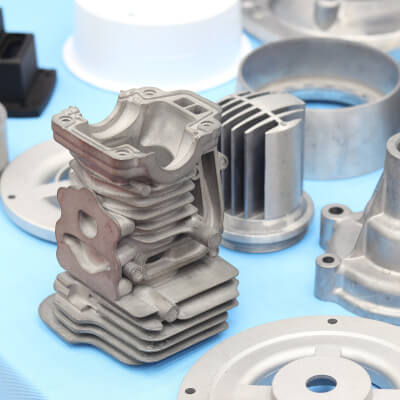

Gensun Precision Machining is a leading provider of die casting services across Asia. Our team of engineers, technicians, and quality control experts work together, ensuring that your product gets done right and on time. As a top die casting supplier in China, we focus on new die casting technologies to produce complex parts with excellent dimensional accuracy and smooth cast surfaces.

Our partner facilities create high-precision die casting parts for customers across a broad range of industries.

What is Die Casting?

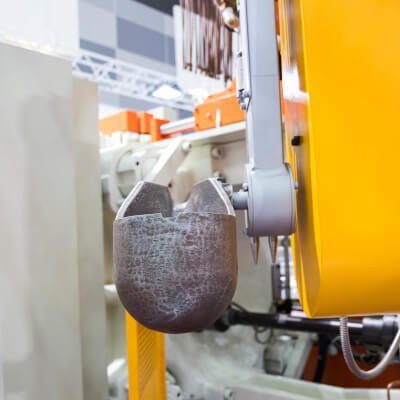

Die casting is a manufacturing process that produces metal parts using molds (also called dies). It involves forcing molten metal into a mold cavity (under high pressures) to create the desired metal parts.

The mold consists of two halves (usually made of heat-resistant steel grades) that form a cavity into which the liquid metal is pressed at pressures ranging from 1,000 to 20,000 psi. The die casting process comes in two typesㅡwhich are hot chamber and cold chamber die casting processes.

Both processes are suitable for fabricating high-quality die-cast parts; they only differ slightly in their casting method. The ideal die casting process primarily depends on the type of metal and part you intend to fabricate.

Hot Chamber and Cold Chamber Die Casting

The hot chamber die casting process, also called hot casting, involves completely immersing the cylinder chamber of the injection mechanism into the molten metal bath before beginning the casting process.

Through a metal feed system, molten metal is pumped into the die cavity to create the desired shape. The hot chamber die casting method is ideal for metals with low melting point temperatures (or metals that won’t dissolve when heated), such as zinc, lead, and magnesium alloys. The process also offers higher production rates than the cold chamber process.

Unlike in hot chamber die casting, the cold chamber die casting process eliminates the need for immersing the injection mechanism into the motel metal bath. Instead, the metal is contained in a holding pot and on a furnace to melt it to the necessary temperature.

Next, the molten metal is ladled from the pot into the die casting machine to create die-cast parts. The cold chamber die casting process is ideal when working with materials having high melting point temperatures like aluminum and copper.

Advantages of Gensun’s Die Casting Services

- Take advantage of state-of-the-art die casting technologies, including die casting machines, to get your product done right and on time.

- We adhere strictly to the design for manufacturing (DFM) criteriaㅡwhich means we help you design parts and optimize mold designs for ease of manufacturing. This reduces our start-up, material, and feature costs, providing you with cost-competitive manufacturing services.

- Our state-of-the-art die casting technologies are compatible with various materials, including zinc and aluminum alloys.

- We complement our precision die casting services with full-scale surface tooling and surface finishing processes like plating, painting, polishing, and powder coating. Our factory is also equipped with state-of-the-art CNC machines to handle intricate part design and assembly.

- Our die casting services are well suited for high volume production of simple and complex parts, making it perfect for customers looking to scale their product development projects.

- We are located in southern China’s Greater Bay Area and not too far from shipping ports, allowing us to provide you with rapid manufacturing services.

- We’ve been in business for nearly 20 years, providing second-to-none manufacturing services for customers across a broad range of industries.

Request a Quote for Die Cast Parts

Do you need a quote for your die cast parts? Contact us now by phone, email, or through our contact form.