CNC Machining Services in China

Get High-Quality CNC Machined Parts from a Trusted China Manufacturer

CNC Machining Services

Are you looking for a reliable and quick-turn provider of CNC machining services? You’ve come to the right place!

Using state-of-the-art CNC technologies, our unmatched team of machinists, engineers, and quality control experts works together to ensure your products are done right and shipped on time.

At Gensun, we’ve designed our ISO 9001: 2015 certified CNC manufacturing facility for rapid prototyping and low-volume production of a broad range of components.

Our CNC machining services also complement our other manufacturing capabilities (like 3D printing and injection molding), providing you with an all-encompassing manufacturing solution.

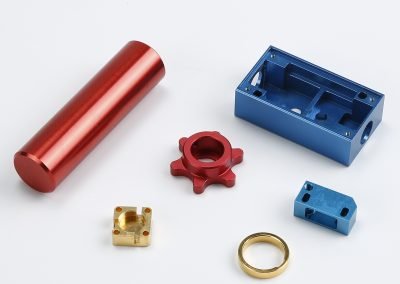

We produce simple and complex precision machined parts in a broad range of materials and surface finishes.

What is CNC Machining?

Computer numerical control (CNC) machining is a subtractive manufacturing processㅡwhich means it uses machine tools to remove portions of material from a workpiece till it forms the desired shape.

A computer program (also called G-code) controls the sequence by which CNC machine tools (or workpiece) move against each other to create the desired parts.

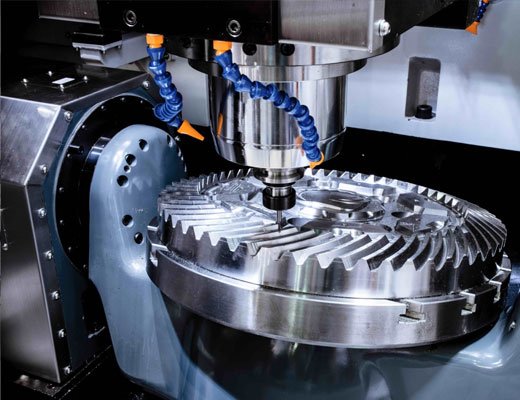

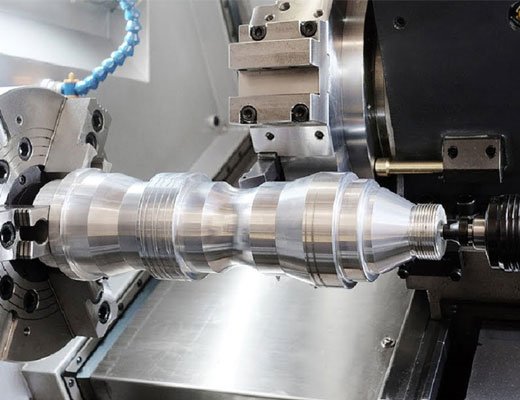

Standard CNC machines include multi-axis CNC milling machines, lathes (or turning machines), and routers. Although all CNC machine types rely on computer instructions to perform subtractive manufacturing, they differ slightly in their modes of operation.

For instance, CNC milling machines operate by holding the workpiece in place as the cutting tool rotates against it. In contrast, CNC turning machines create parts by holding the cutting tool in place as the workpiece rotates against it.

High Precision CNC Machined Parts

CNC machines can create a broad range of features and high-precision parts. For instance, CNC milling machines are ideal for producing cavities, angled shapes, holes, and slots.

In contrast, CNC lathes are suitable for creating cylindrical shapes or parts that are symmetrical near their axis.

Nevertheless, CNC milling and turning machines can achieve tolerances as tight as ±0.001mm.

They are also compatible with a broad range of materials, including metals and plastics, so long as these materials are available in blocks. This is not the case with additive manufacturing technologies (like 3D printing), which are only compatible with plastics and a few metals.

Advantages of Gensun’s Services

#1 High-quality and reliable

We have highly trained engineers, machinists, and quality control experts capable of getting your product done right the first time. Our team of experts follows industry standards by using best-in-class software, state-of-the-art CNC technologies, and quality control tools to create customers’ parts.

#2 Broad range of material options

We offer a wide range of material options, including metal parts (like aluminum, steel, stainless steel, brass, copper), plastic parts (like POM, PTFE, PC, PEEK, PET), and special alloys (like Kovar, Invar, Inconel, Titanium, Mocu).

#3 World-class machine shop

We adhere strictly to several key industrial, quality, and environmental standards. For instance, our machine shop is ISO 9001:2015 certified for quality management systems, ISO 14001:2015 for environmental management systems, and ISO 13485:2016 certified to fabricate medical devices.

#4 Cost-effective manufacturing services

At Gensun, we adhere strictly to the design for manufacturing (DFM) criteriaㅡwhich means we design parts and optimize designs for ease of manufacturing. This reduces our start-up, material, and feature costs, providing you with a cost-effective manufacturing service.

#5 Fast manufacturing and delivery

Not only do we get your products done right, but we are also located in southern China’s Greater Bay Area. We’re close to major shipping ports, allowing us to get your products to you swiftly.

#6 Custom CNC machining

We offer custom CNC machining services to our customers that want to replace obsolete parts, work with difficult materials, or manufacture parts with special requirements.

Our China CNC Machining Services

CNC Milling

Your precision machined prototype or production parts, produced using our advanced CNC machining stations.

CNC Turning

Your precision turned parts, produced by our skilled machinists on imported or domestic CNC lathes in China.

Industries We Serve

- Aerospace & Defense

- Optical Communication

- Robotics & Automation

- Automotive

- Electronics

- Medical Equipment

- Semiconductor

- Energy

CNC machining has been at the forefront of machining technologies used in the aerospace and defense industry for over three decades. And this is due to the extremely high precision CNC machines offer, making them ideal for creating many safety-critical parts, such as landing gear and engine components, missiles, and combat vehicles.

While precision remains integral to the performance of optical components and systems, most of the materials used for laser housing products and other optical components are extremely difficult to machine. CNC machines are helping to accurately fabricate optical communication parts made of silumin, iron-nickel, and copper alloy materials.

CNC machining is a widely used process in the robotics and automation industry for fabricating robotic end effectors, custom jigs and features, and storage units. Because CNC machines can achieve tolerances of ±0.05 mm and surface roughness of Ra 0.8μm, product designers can ensure robotic part dimensional accuracy.

The automotive industry relies on CNC machining to create prototype components made from specialty lightweight metal alloys and composites. Machinable automotive parts include engines, roof panels, lighting, and transmission systems, among others. CNC machining is also useful for creating many custom automotive parts, especially for limited-edition luxury vehicles.

CNC machining is the most popular machining technology in the electronics industry because of its advantages such as low labor costs, high productivity, and precise complex shapes manufacturing. 3-, 4-, and 5-axis CNC machines are especially useful for fabricating electronics housings, panels, heat sinks, and other miniaturized electronics parts.

In recent years, the medical industry has seen a high demand for high-precision machining services for producing implants, medical devices, and surgical instruments. Through custom CNC machining, machine shops accurately create these parts while meeting the requirements of several regulatory bodies, such as the U.S Food and Drug Administration (FDA) and ISO 13485.

As the demand grows for more stringent semiconductor component specifications, the semiconductor industry is adapting accordingly by getting rid of conventional machining techniques and relying on CNC machining to manufacture parts. CNC machining is also making it possible for semiconductor designers to easily achieve different surface finishes, including anodizing, nickel-plated, and masked finishes.

Solar, wind, and hydropower turbines and generators play a vital role in powering other industries. These power generation facilities feature many complex components made of different metal alloys and reinforced carbon fiber plastics. They are usually fabricated using CNC machines.

How CNC Machining Works: An Overview

How Does CNC Machining Work?

CNC machining is a subtractive manufacturing process that employs computerized controls and machine tools to remove portions of a stock material till the desired custom part is made from the workpiece.

The machining process starts with the creation of a CAD (Computer-Aided Design) model of the desired part, which is then loaded into a CAM (Computer-Aided Manufacturing) software and converted to a set of computer instructions.

This set of instructions (or G-code) allows the machine to execute different cutting operations at high speed (thousands of RPM) till the desired custom part is made.

How Does CNC Machining Compare to 3D Printing?

Both CNC machining and 3D printing rely on CAD files and computer inputs to transform a starting material into desired custom parts. However, unlike the subtractive CNC machining process, 3D printing is an additive machining process. It revolves around adding materials in layers to build the desired custom part.

CNC machining offers a wide range of material options, whereas 3D printing only works with plastics, polymers, and a few metals that are available in powdered form. Additionally, CNC machined parts are usually stronger than 3D printed parts; as such, CNC machining is ideal for prototyping and production of functional parts.

What are the Different Types of CNC Machining?

CNC machines come in many varieties, with each type having its unique functions.

CNC turning and milling machines feature built-in tools for cutting and drilling the workpiece till the custom CNC part is made. They are available in 3-, 4-, and 5-axis configurations, depending on the part complexity.

The CNC milling process involves the workpiece being held in place while the cutting tools rotate around it, whereas in CNC turning, the workpiece is rotated around the fixed cutting tools to create the desired shape.

Unlike CNC milling and turning machines that rely on cutting tools, CNC Electric Discharge Machines (EDM) utilize electric sparks to manipulate materials into the desired shape.

Request a Quote

Do you need a quote for your high-precision part? Contact us now by phone, email, or through our contact form.