Modern machinery usually comprises several parts assembled to make a fully-operational product. However, these pieces of machinery usually generate huge forces and experience vibrations large enough to disassemble the parts and cause failure.

Fasteners are essential pieces of hardware helping to mitigate this challenge by joining two (or more) components together. However, fasteners come in several types, with each type having its suitability for different applications.

Here, we discuss the different types of fasteners commonly used today. This article will help you make an informed decision when choosing fasteners for your product design project.

What is a Fastener?

“Fastener” is a general term for a piece of hardware that mechanically joins two (or more) components together. Fasteners include various tools, usually made of metals and broadly classified as permanent and temporary fasteners.

As its name implies, a permanent fastener creates a permanent joint between two parts. They are single-use devicesㅡwhich means you can only use them once because removing these fasteners destroys them. In contrast, temporary fasteners allow easy removal and reuse while offering comparable (or even better) strength than permanent fasteners.

5 Common Types of Fasteners

Type 1: Screws

A screw is a temporary fastener consisting of a head and shank with sharp threads. To join parts together using a screw, you’d have to rotate the screw into the parts using a screwdriver. This rotating action causes the screw threads to cut threads into the material, creating a firm mechanical joint and preventing pull-out.

Screw fasteners come in several types, but the machine screw, deck screw, and wood screw are among the most popular ones.

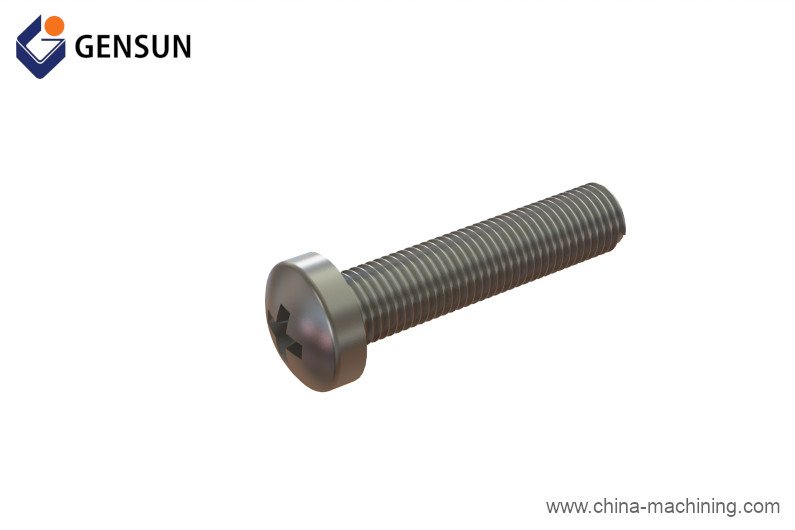

Machine screws

Machine screws feature accurate fine threads and are ideal for assembling machine components. Unlike other screw fastening processes that create holes in components, machine screws are installed into pre-drilled holes. This makes them easy to remove, especially when performing maintenance activities or replacing components.

Figure 1: Machine screw

Deck screws

Deck screws are ideal for assembling soft to medium density deck boards. They feature a square drive and bulge head that eliminates stripping effectsㅡwhich occurs when the screw’s head wears out.

Figure 2: Deck Screw

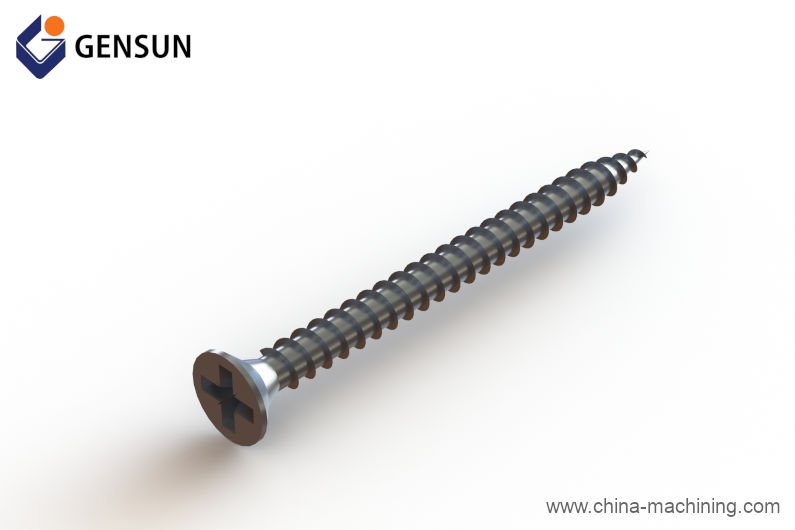

Wood screws

Wood screws are sharp-pointed screws with coarse threads. They are ideal for fastening wooden or composite parts, especially for non-structural applications.

Figure 3: Wood screw

Type 2: Bolts

Bolts have a similar structure to screwsㅡthey have external threads (or male threads) that start from their tips. However, unlike screws, bolts are not self-threading (they do not cut threads into the material). Instead, they require preformed parts (like nuts) and pre-tapped holes to engage and create mechanical joints. Here is a list of the most popular bolt types.

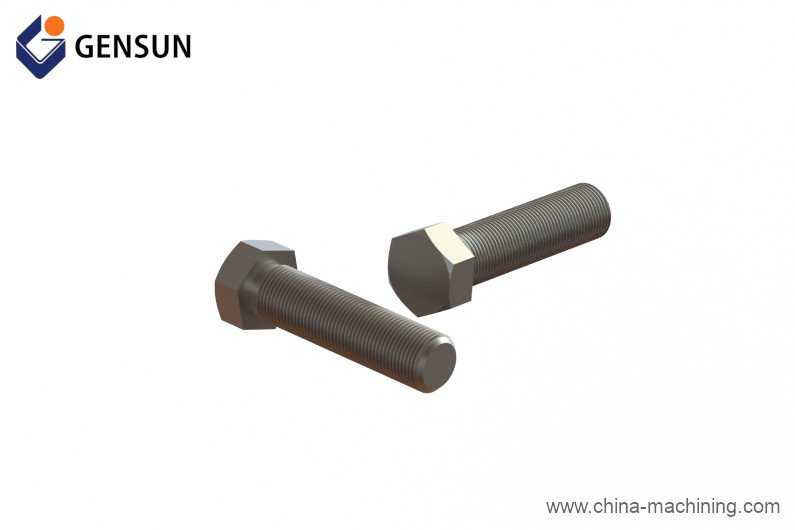

Hexagonal head bolts

Hexagonal head bolts have a six-sided head and a fully (or partially) threaded shank. These bolts offer high tensile strength, making them ideal for heavy-duty fixing and fastening applications like automotive parts assembly and construction projects.

Figure 4: Hexagonal head bolts

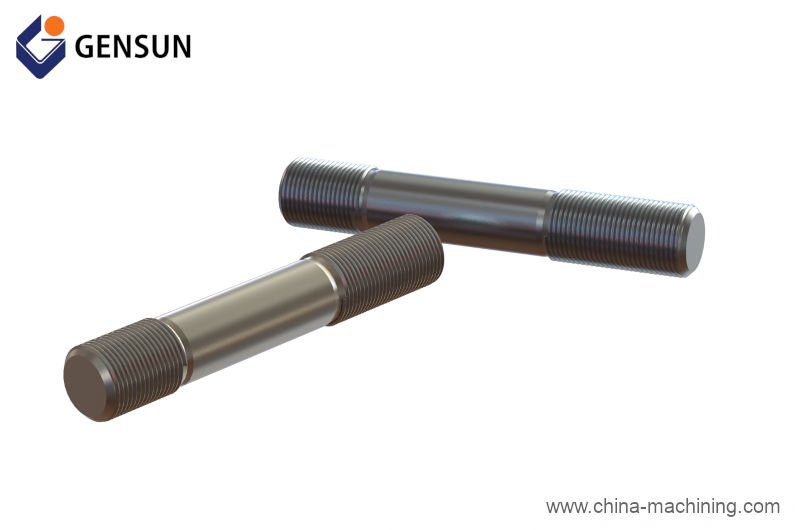

Double-end bolts

Double-end bolts are basically threaded rods with equal thread lengths at both ends to accommodate nuts. They are ideal for attaching flanges or pipes.

Figure 5: Double-end bolts

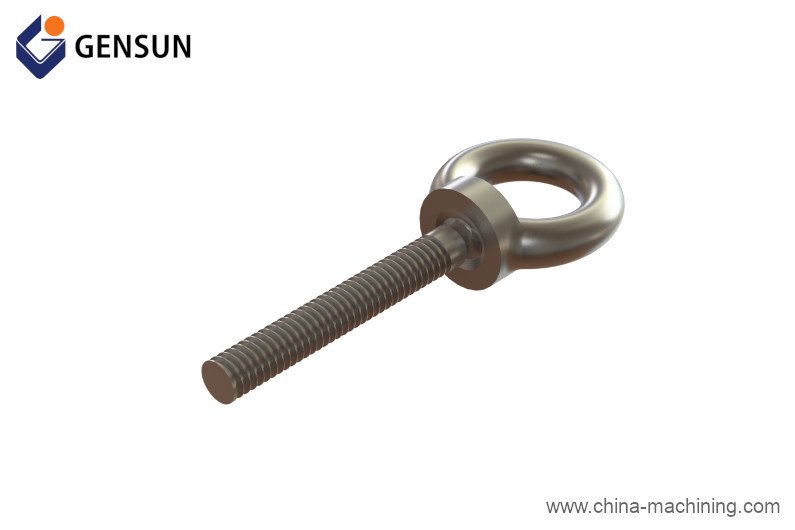

Eye bolts

An eye bolt features a loop at one end and a threaded shank at the other end, as shown in Figure 6. These bolts have high strength and are ideal for anchoring, rigging, hoisting, or pulling applications. For instance, an eye bolt with a ¼-inch shank can hold up to 500 lb of pulling force.

Figure 6: Eye bolts

Type 3: Nuts

A nut is a fastener with a threaded hole (or female threads) that is typically used with a corresponding bolt to form a bolted joint. One notable advantage of using nuts and bolts as fasteners is that it allows you to assemble heavy machinery while offering high strength and ease of installation (and removal). The common types of nuts include:

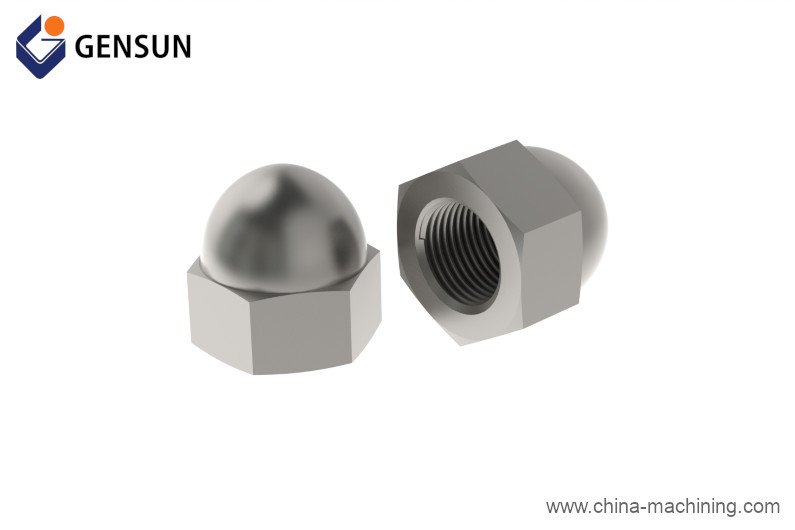

Cap Nuts

Cap nuts are traditional hexagonal head nuts with a closed-end in the shape of a dome. They are ideal for applications where protection of the bolt is important after assembly, for example, construction and automotive assembly projects.

Figure 7: Cap nuts

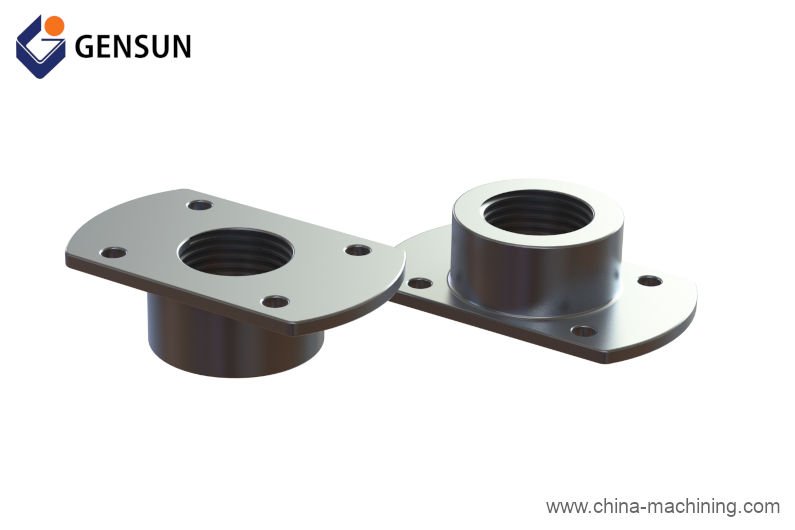

Weld Nuts

Weld nuts are designed to be welded to a workpiece. You should opt for weld nuts if you’re looking to fasten parts in difficult-to-reach regions.

Figure 8: Weld nuts

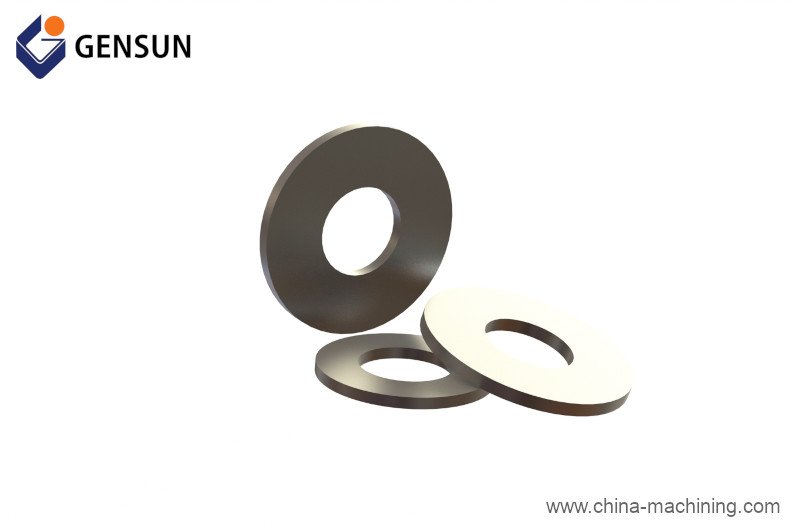

Type 4: Washers

Washers are circular metallic discs used in conjunction with bolts and nuts. They help reduce friction and ensure even load distribution from nuts and bolts on the fastened part. Washers come in two types: the plain washer and the spring washer.

Plain washers (also called flat washers) take the shape of a disk with a hole in the middle. They are the most commonly used washer type, especially in applications where the only requirement is to ensure even load distribution from nuts and bolts on components.

Figure 9: Plain Washer

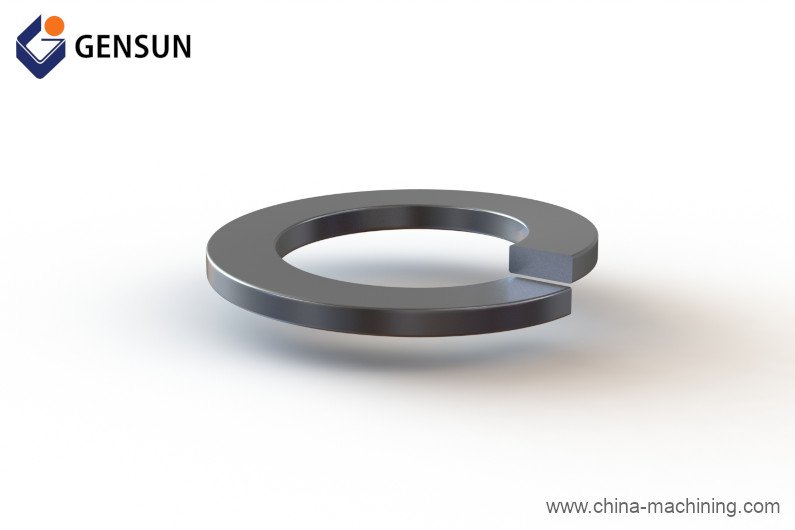

In contrast, spring washers act like springs, preventing the unintended loosening of fasteners due to parts vibration.

Figure 10: Spring Washer

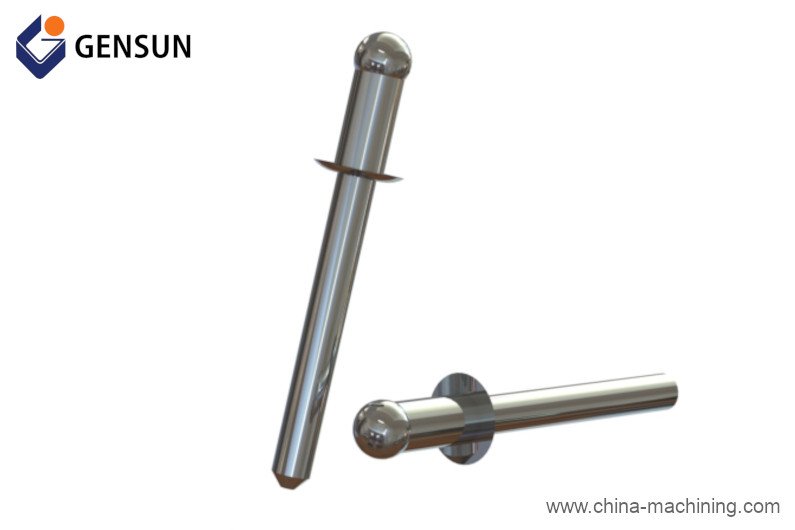

Type 5: Rivets

Rivets are permanent fasteners that feature a shaft that is inserted into holes to join parts together. When you insert a rivet into the components you want to assemble, it forms a permanent head at the other end, which prevents the rivet from removing.

Figure 11: Pop rivet

Rivets form a stronger and tighter joint than screws of the same diameter. As a result, they are ideal in applications that require strong mechanical joints like aircraft construction, aluminum watercraft.

Gensun Precision Machining is a leading provider of manufacturing services across Asia. Not only do we have the best-in-class equipment to fabricate your parts, but our highly experienced engineers and technicians help you see your product vision through to completion.

Learn more about our CNC machining services.