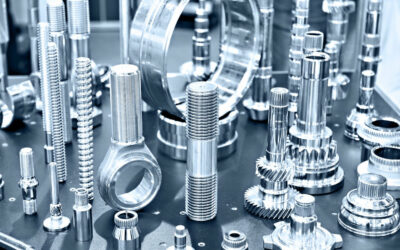

Companies around the world use CNC machining to craft high-quality components from diverse materials like ceramics, wood, and composites. Metal and plastic take the forefront in mass production, with metals enjoying wider machinability. Machinists can adeptly tackle...

Blog

Machining ABS Plastic: The Benefits, Challenges, and 5 Important Tips

Plastics are incredibly useful. They’re affordable and very lightweight. They can also offer benefits, like chemical resistance, transparency, elasticity, electrical resistance, and more, depending on the plastic. ABS is a popular plastic for applications that need a...

CNC Machining Stainless Steel: The Benefits, Drawbacks, and Best Alloys

Stainless steel is just one of many classes of steel. It’s best known for its strength and durability, even in wet or corrosive environments. This makes it a very popular metal for both consumer products and industrial applications. This article explains the many...

Comparing the Compressive Strengths of Different Metals

Designers often need to evaluate the strength of different materials when selecting one for their product. In our previous article on metal strength, we explained that there are actually several different types of strength. These include tensile strength, compressive...

Corrosion-Resistant Metals: How to Choose the Right One for Your Project

Corrosion-resistant metals are essential components of many engineering projects. These special alloys provide scientists and engineers with technological solutions that maintain the integrity of their projects for long periods of time, even under the most extreme...

The Melting Points of Metals: Understand the Crucial Role They Play

The melting point of a metal, or any material for that matter, is the temperature at which a solid material changes phase into a liquid. You can think of it like frozen water, where once a certain temperature is reached, the ice melts to become liquid water. For...

3 Lightweight Metals and Their Key Benefits Explained

Steel is the most widely used metal in the world today and offers a great balance of material properties at a good cost. But when steel, at a density of 7.8g/cm³, is too heavy for the application, product designers must turn to one of the lighter materials available....

What is the Strength-to-Weight Ratio, and Why Does it Matter to Engineers?

Engineers must be able to accurately assess and analyze a material's various properties before incorporating it into any application. The strength of a material is important to consider, but so is the weight, as this affects both the carrying capacity and efficiency...

Titanium vs. Aluminum: Which Lightweight Metal is Best for Your Project?

When it comes to machining lightweight metals, two popular options come to mind: titanium and aluminum. Both of these metals are widely used in a variety of industries due to their strength-to-weight ratio, corrosion resistance, and manufacturing capabilities....

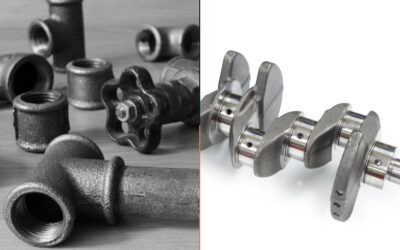

Cast Iron vs. Steel: What Are Their Advantages and Disadvantages?

Both steel and cast iron are popular metals, but they are often used very differently. The key factor distinguishing one from the other is how much carbon each contains, and to a lesser extent, how much silicon. While this may seem like a subtle distinction, it has...