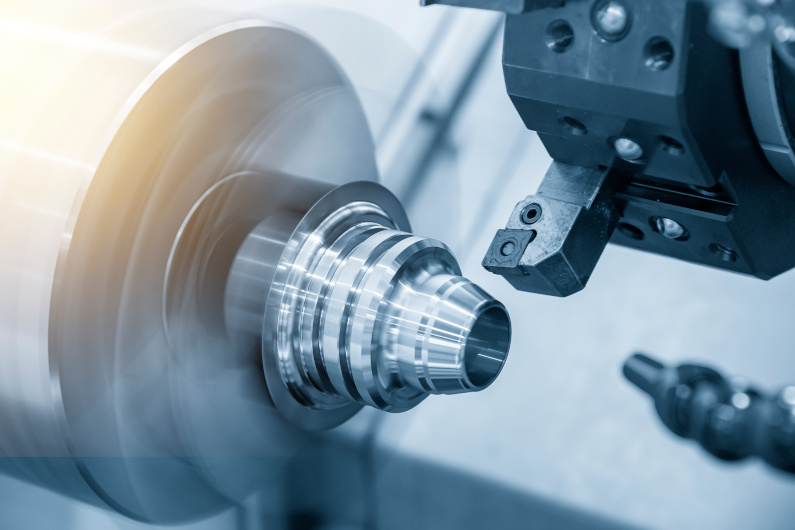

The evolution of CNC machining has been marked by significant technological advancements. From the early days of punch tape and rudimentary programming, CNC machining has evolved to incorporate sophisticated software and high-speed, multi-axis machines.

In recent years, a new technological development has started to make its mark on the field of CNC machining: Artificial Intelligence (AI). AI, with its ability to learn from data, make decisions, and improve over time, is poised to bring about a new wave of innovation in CNC machining.

In this article, we will delve deeper into the role of AI in CNC machining, examining its current applications, future potential, and the challenges it presents. We will also look at how different types of CNC machine shops are adopting AI and the impact it is having on the industry as a whole.

The Impact of AI on CNC Manufacturing

Artificial intelligence is having a profound impact on CNC manufacturing, transforming the way operations are conducted and offering a host of benefits. Here are some key areas where AI is making a significant difference:

1) Continuous Production

One of the most significant impacts of AI in CNC manufacturing is the ability to enable continuous production. AI-powered robots can work non-stop, 24 hours a day, without the need for breaks or downtime.

This is particularly beneficial for mass production and large manufacturing units where maintaining a steady pace of production is crucial. By eliminating the constraints of human fatigue and the need for rest, AI allows for a level of productivity that was previously unattainable. This not only increases the overall output but also ensures faster delivery times.

2) Safe Work Environment

Safety is a paramount concern in any manufacturing environment. AI is contributing to safer work environments by taking over tasks that are dangerous for humans. With machine learning and deep learning systems, machines can handle risky operations without any human involvement. This not only reduces the risk of accidents and injuries but also allows human workers to focus on tasks that require critical thinking and creativity.

3) Direct Automation

AI and machine learning are particularly well-suited for repetitive and recurring tasks. These tasks, which can be monotonous and prone to human error, can be automated with AI, leading to greater efficiency and consistency. This direct automation is beneficial for manufacturers as it helps maintain constancy in production and reduces the likelihood of errors that can lead to waste or rework.

4) Increase in Demand

The integration of AI into CNC machining is leading to a rise in demand for this manufacturing method. As AI and machine learning continue to improve the quality, precision, and overall performance of CNC machining, more industries are recognizing its potential.

Industries such as automotive, medical, aerospace, and marine are increasingly relying on CNC machining for its efficiency and effectiveness. As a result, we’re seeing a significant rise in demand for CNC machining, a trend that is expected to continue as AI technology advances.

AI-Powered Tools and Machines

AI-powered tools and machines are designed to leverage machine learning and deep learning technologies to enhance their functionality and performance. Unlike traditional machines, which follow pre-programmed instructions, AI-powered machines have the ability to learn from data, adapt to new inputs, and improve their performance over time.

For instance, AI-powered machines can respond to voice commands and make decisions for repetitive tasks. They can analyze and process repetitive patterns and respond accordingly, allowing manufacturers to produce quality parts with little to no errors. This not only increases the accuracy and design-orientation of the parts being produced but also reduces wastage and cost per unit for the manufacturers.

Moreover, AI-powered machines are equipped to handle more complex tasks. For example, the tool path, which is the way a tool travels through a workpiece, can be optimized by AI analysis of the data. This allows the machine to adjust the tool path to one that generates the highest productivity level and least wear, thereby enhancing the overall efficiency of the machining process.

Ability of AI Machines to Process Large Data Sets

One of the key advantages of AI machines over traditional ones is their ability to process large data sets. In the context of CNC machining, this means that AI machines can gather, process, receive, and respond to a vast amount of data, which can be used to optimize the machining process.

For instance, AI can be used to automatically process operations data to provide the information needed to make key decisions and take action. This streamlines the analysis process, allowing for more informed and efficient decision-making. Furthermore, AI can be used to predict energy consumption during machining operations, providing an efficient way to manage energy consumption and achieve long-term sustainability in the manufacturing industry.

Adoption of AI in CNC Machine Shops

The integration of Artificial Intelligence into CNC machining is a trend that’s gaining momentum, with more and more machine shops adopting AI into their processes. However, the adoption of AI in CNC machine shops varies depending on several factors, including the size of the organization and the nature of its operations.

Potential Drawbacks and Challenges

Despite its benefits, the adoption of AI in CNC machining is not without its challenges. For one, it requires a significant investment in terms of both time and money. Determining whether the long-term use of AI technology is beneficial for a particular CNC machining operation can be a complex process that requires careful analysis and planning.

Not all CNC machine shops may be able to fully capitalize on the advantages of AI. Small CNC machine shops, for instance, may fulfill a niche and not feel the need to grow their skill sets. Or, their limited processes may lack the ability to capitalize on automation’s advantages. If their equipment and software systems aren’t automation-ready, the complexity of fully automated systems could become a burden.

Difference in AI Adoption Between Small and Large CNC Machine Shops

The adoption of AI in CNC machine shops also varies depending on the size of the organization. Medium to large organizations are generally better positioned to adopt AI in the future. When you combine today’s labor shortage (and skills gap) with the revolution in technology, it’s clear that AI is elevating the importance of experts who program, operate, and truly understand automated CNC machines.

The increased efficiencies gained from AI adoption allow industry engineers in these organizations to perform more value-added tasks, expand quality control efforts, and create smarter operations. This not only enhances the overall productivity and efficiency of these organizations but also positions them to better meet the increasing demand for CNC machining.

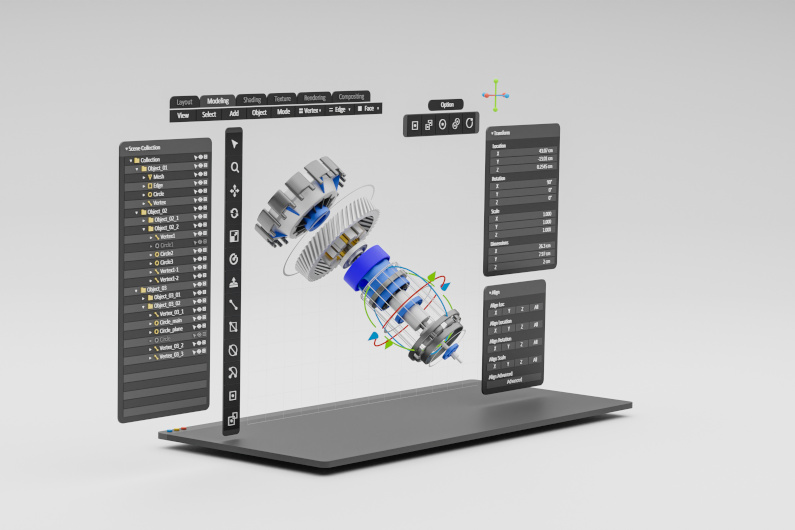

The Future of CNC Machining with AI

As AI technology progresses, it’s likely that AI will become advanced enough to be linked to the design software and amend designs automatically for improved results. Generative design, an iterative process to design that automatically optimizes designs, is being used with software such as Autodesk Dreamcatcher linking directly into additive manufacturing (3D printing) or subtractive manufacturing (CNC machining) processes.

The future of CNC machining will almost certainly be a more linked-up one, with the whole manufacturing process linked via cloud computing, with AI optimization, diagnostics, and fault correction. However, human CNC machinists will still be required in the foreseeable future to operate the computer, load the designs, oversee the process, and rectify any faults.

The overall impact of AI and machine learning on CNC machining operations is profound and far-reaching. While there are challenges to be overcome, the potential benefits of these technologies are immense. As we continue to explore and harness the power of AI and machine learning, the future of CNC machining looks set to be one of increased efficiency, productivity, and innovation. Finding the right partner to take advantage of this technology is necessary to ensure your firm does not fall behind the curve.

About Gensun Precision Machining

Gensun Precision Machining is a leading provider of CNC machining services. We have a team of highly qualified technicians and engineers to help you create the parts you need. Reach out today to learn more about our services.