Take a look around, identifying and naming all the products in your surroundings, including phones, tablets, laptops, wrist watches, vehicles, and desks. Most, if not all of these items, are end products of CNC machining.

CNC machining is a manufacturing process that uses computerized instructions (or a computer program) to accurately and precisely create the parts you need.

The computerized nature—coupled with the high accuracy, precision, and a broad range of material compatibility—of CNC machining make it one of the most in-demand manufacturing processes today. For example, Tech Giant Apple had to ditch conventional machining and rely on CNC machining to manufacture the unibody outer shell of the MacBook.

Do you want to learn about how CNC machines work, the CNC machining process, and the different types of CNC machines available today? You’re in the right place!

What is CNC, and How Do CNC Machines Work?

CNC stands for Computer Numerical Control; this is simply a method for automating the control of machine tools.

Computer numerical control machines rely on computer instructions and a CAM (computer-aided manufacturing) program to control, automate and monitor machine tools’ movement to create the desired part.

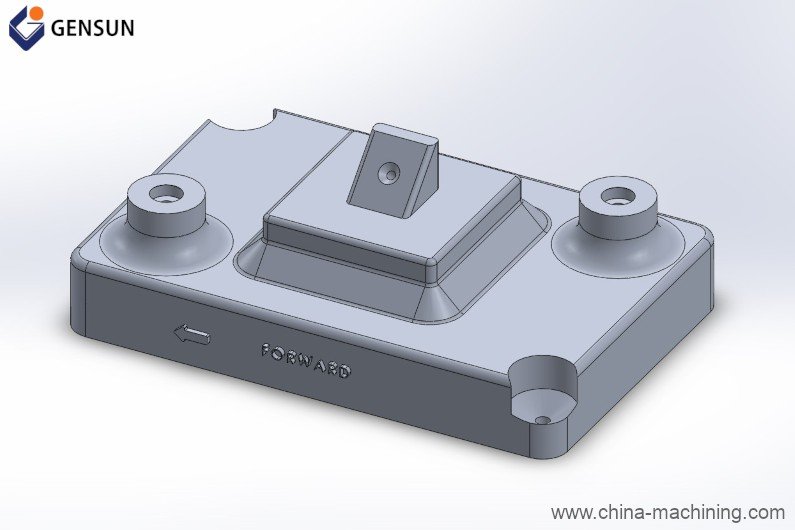

Look at it this way. A CNC machine takes a stock piece of material (for example, an aluminum block) and transforms it into a finished product through controlled material removal processes.

Let’s break the CNC machining process down even further.

The CNC Machining Process Explained

We can break down the CNC machining process into five distinct steps:

#1 Create Your 2D and 3D Designs

The first step of the CNC machining process is to create your part’s 2D and 3D drawings using computer-aided design (CAD) or computer-aided manufacturing (CAM) software like SolidWorks and Autodesk Inventor. When creating your 2D and 3D drawings, you must specify all important dimensions, features with tolerances, and surfaces with specific surface finishing requirements.

The goal is to make an accurate representation of the part (or product) you’re looking to create.

Learn More: An Overview of CNC CAD Design

#2 Save Your Design Using the Best 3D CAD File Formats

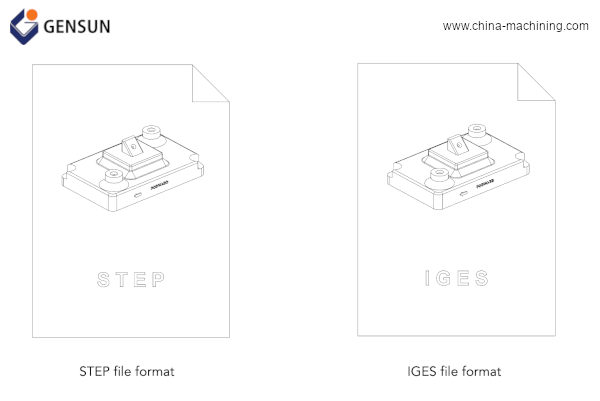

Two commonly used CNC-compatible file formats used in CNC machining are the STEP and IGES file formats.

The STEP format (sometimes called the STP format) is widely regarded as the best file format to share your 3D models. This is because the format is neutral and not owned by any particular 3D CAD software vendor. As a result, your product development team (or machine shop) will have no problem accessing (or modifying) your designs regardless of the 3D CAD software you used to create them.

In contrast, the IGES format (pronounced ‘eye-jess’) is an older file format than the STEP format. It is available in almost every 3D CAD package, meaning your machinist will have no problem accessing it to fabricate your products. However, IGES files are usually larger than the STEP file for the same product design. Therefore, the STEP file format might be the ideal option if you need to send large designs to your manufacturer via email.

Other 3D CAD file formats used in CNC machining include the AP214, STL, DWG, and DXF file formats.

#3 The Machinist Generates a Toolpath

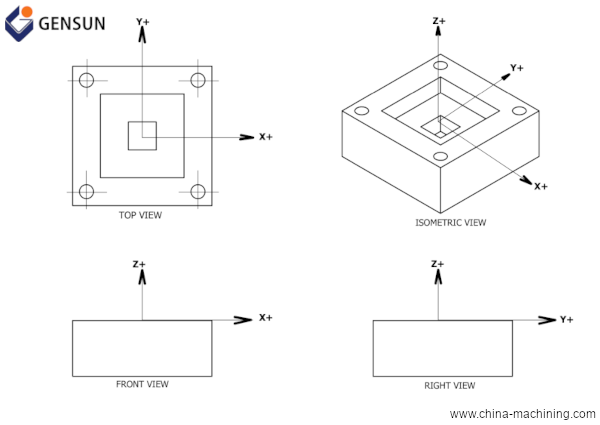

A toolpath is a series of coordinate locations (or the path through space) that a CNC cutting tool will follow during the machining process to produce the desired geometry of the workpiece.

To help better understand “toolpath” in CNC machining, let’s consider the image below where we have a block whose features reside on the XY plane. To create the desired part (a block with two cuboid cavities), you must first position your cutting tool to make cuts along the Z-axis before moving along the XY plane.

CAM software typically has functionalities that allow machinists to define their machining strategy, including the type of cutting tools to use, feed rates, and cutting tool speed.

#4 The Machinist Converts the Machining Parameters into CNC-compatible File

The final step the machinist takes on the CAM software is to convert the machining strategy into what is called the G-code. A G-code is a computer language that a CNC machine can understand and execute; it tells the CNC machine precisely what steps to execute to make your part.

After generating the G-code, the machinist exports it to the CNC machine.

Learn More: What are G-Code and M-Code?

#5 The Machinist Executes the Machining Operation

This is the phase where the machinist inserts the workpiece into the CNC machine and installs all the cutting tools required for the machining operation. Once these steps have been completed, the machinist initiates the machining program to create parts autonomously.

Types of CNC Machines

CNC machines come in several types, with each type having its functions and machining capability. Four of the most commonly used CNC machines today include:

- CNC milling machines

- 5-axis CNC milling machines

- CNC turning machines

- CNC drilling machines

CNC Milling Machines

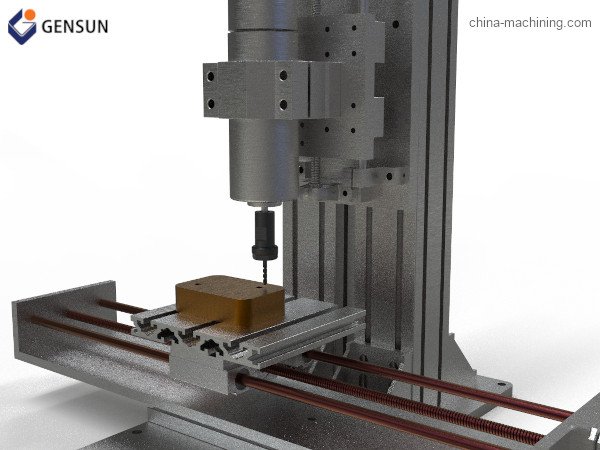

CNC milling machines (or CNC mills) create parts by rotating a cutting tool against a stationary workpiece. This operation removes material from the workpiece to form the desired part. The sequence of movement of the cutting tool is controlled by computer numerical control technology.

You’ll typically find CNC milling machines as three-axis machines — which means that they operate along three independent axes (X-axis, Y-axis, and Z-axis) to fabricate parts. However, CNC milling technology has recently advanced to complex machines capable of operating along several independent axes (for example, the 5-axis CNC milling machine).

5-Axis CNC milling machine

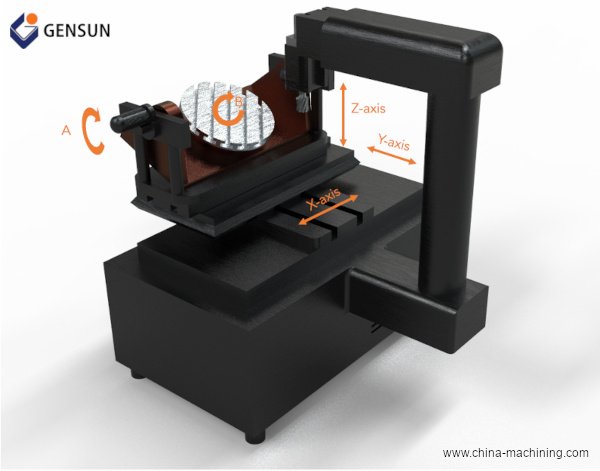

A 5-axis CNC milling machine is a type of milling machine that operates along five independent axes — which are the X-axis, Y-axis, Z-axis, and A and B rotational axes. This allows you to approach your workpiece in all directions to create intricate geometries.

The 5-axis CNC milling machine allows the workpiece and a cutting tool to move simultaneously during operation, saving time and allowing you to create cavities and angled cuts accurately and precisely.

CNC Turning Machines

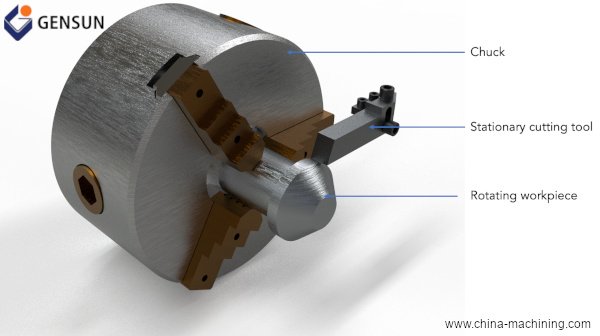

CNC turning machines (or CNC lathes) are similar to CNC milling machines — they rely on the automated nature of CNC technology to create cuts and machine parts. However, unlike CNC milling machines, a CNC turning machine creates cuts by rotating the workpiece against a stationary cutting tool.

A typical CNC turning machine assembly features a chuck holding the workpiece. The chuck is attached to a spindle that rotates the workpiece against the stationary cutting tool. This mode of operation removes portions of material from the workpiece, allowing you to create your desired parts.

CNC turning machines are ideal for machining cylindrical shapes; they allow you to perform turning operations, including taper turning, drilling, knurling, grooving, and parting operations.

CNC Drilling Machines

A CNC drilling machine utilizes a rotating cutting tool to create cuts in a stationary workpiece, like the CNC milling machines. However, CNC drilling machines are especially suited for producing holes to accommodate bolts or machine screws for assembly purposes. You will also find them useful for creating letterings or engravings on a workpiece.

Other types of CNC machines include CNC plasma cutters, CNC laser cutting machines, and CNC Electric Discharge Machines (EDM). These machines have similar functions and machining capabilities. However, they differ in their modes of operations and their cutting mechanism. For more information, take a look at our article about the different types of CNC machines.

Choosing the Ideal CNC Machine Shop for Your Manufacturing Project

Now that you know what CNC machining is, how it operates, and the broad range of CNC machine types, you’d agree that CNC machining is truly one of the best machining technologies available today.

However, if you plan to outsource the manufacturing phase of your product development, the success of your project primarily depends on the CNC machine shop you work with. Top-notch CNC machine shops have top-of-the-line manufacturing technologies, highly experienced CNC machinists and quality control experts who work together to get your product done correctly. In addition, these shops usually meet the requirements of several regulatory standards like ISO 9001, ISO 14001, and ISO 13485 standards.

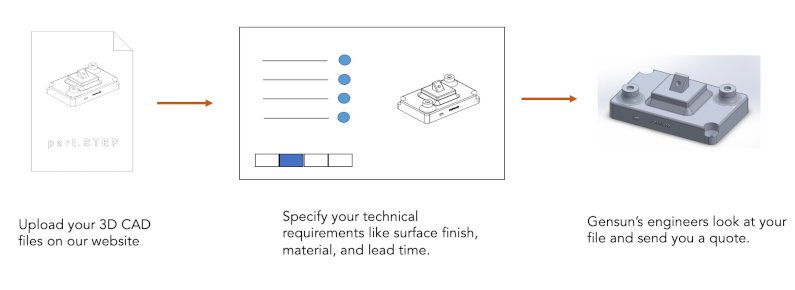

Ideal machine shops also typically have an instant quote tool available online. For example, Gensun Precision Machining has a quote tool that allows you to upload your 3D CAD file (in several file formats) and specify your requirements to get a quote for your project.

CNC Machining: Gensun Precision Can Help

Gensun Precision Machining is a leading provider of CNC machining services across the globe. Backed by nearly two decades of CNC machining experience, we have a reputation for creating high-quality metal and plastic parts for customers in various industries.

In addition, our facility is ISO 9001 certified for quality management, ISO 14001 certified for environmental management, and ISO 13485 certified to serve the medical industry. We have completed over 100,000 projects with several innovative companies serving different industries.

Tell us about your project and let our highly qualified engineers, machine operators, and quality control team create parts precisely to your specification.

Note: This article was originally published in September of 2021 and was updated in June of 2022