Engineers must be able to accurately assess and analyze a material’s various properties before incorporating it into any application. The strength of a material is important to consider, but so is the weight, as this affects both the carrying capacity and efficiency of the design. The strength-to-weight ratio also helps engineers find cost savings in materials without sacrificing a high level of performance from their product.

As such, engineers must have an understanding not just of the available materials but also of how they interact with each other in order to create lasting and effective products. With the right knowledge and preparedness, engineers can reliably create complex products that stand the test of time. This article will discuss the strength-to-weight ratio and how it impacts design.

What is Strength-to-Weight Ratio?

Strength-to-weight ratio is a measure of the strength of an object divided by its mass or weight. It is used to determine the efficiency and performance of any given material or component. Because of this key metric, engineers are able to produce top-quality products that take up less material and are designed more efficiently.

Strength-to-weight ratio is essential for assessing how much use a certain structure can take while making sure the weight limit isn’t exceeded. This fundamental property not only helps engineers find structural solutions that fit within predetermined parameters and restrictions but also enables them to craft designs with optimal strength and mass characteristics.

The Strength-to-Weight Ratio and Material Selection

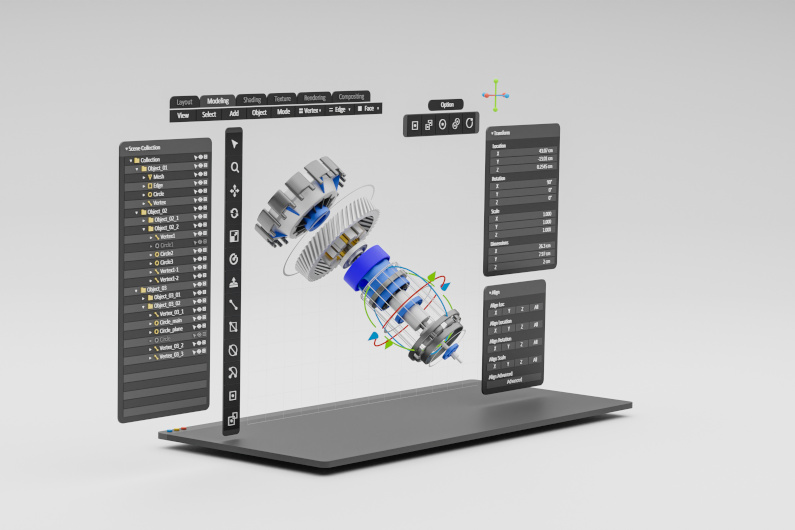

The strength-to-weight ratio of materials is an important physical property that engineers value when designing and building products. Optimal ratios will depend on the application, but what matters most is that lighter materials don’t sacrifice strength capabilities. Incorporating a material with a high strength-to-weight ratio into a vehicle, for example, helps improve the overall power and performance while also decreasing the product weight. This property ultimately increases the efficiency and speed of the product.

Lightweight materials are often used to achieve desired strength-to-weight ratios, as they help create designs that are durable while not compromising on strength. Careful analysis must be applied to ensure that all components meet expected standards and ensure maximum load capacity with no compromise in performance. With a proper understanding of strength-to-weight ratios, Engineers can create designs that perform effectively under a variety of conditions with utmost confidence and efficiency.

Why Does This Ratio Matter to Engineers?

Strength-to-weight ratio is an important consideration for engineers as it helps them to determine the weight of a given material or component and compare it to its performance in a given application.

By optimizing the ratio, engineers can save costs associated with materials that lack the required strength for a specific application, as well as increase efficiency and performance. This property helps ensure that materials used in any industrial project are well-suited to their purpose while also providing cost savings and improved performance.

Strength-to-Weight Ratio Factors

Strength-to-weight ratio is affected by various materials and components such as metals, carbon fiber and composites, wood, plastics, ceramics, and glass. Factors such as modulus of elasticity, yield stress, ultimate tensile strength, and strain hardening rate all come into play.

Metals are usually the most commonly used material in engineering projects due to their high strength-to-weight ratio. Carbon fiber and composites can also be very light while providing excellent strength and durability. Wood can provide good strength at a relatively low weight, but it can be prone to warping and shrinkage.

Plastics tend to have lower strength-to-weight ratios than metals and are more susceptible to damage from UV exposure. Ceramics generally have low strengths combined with heavy weights but can be useful for applications that require insulation or heat resistance. Glass also tends to have a lower strength-to-weight ratio than metals but has great resistance to corrosion and abrasion.

Strength-to-Weight Ratio Material Applications

Engineering materials that require a high strength-to-weight ratio are critical for many applications, from aerospace vehicles to autonomous robots. Due to their combination of lightweight and strength, metals such as titanium and aluminum alloys have made them the primary materials used in optimizing the weight reduction of modern vehicles.

Despite their high cost, composite materials such as carbon fiber have become increasingly popular due to their unique properties, which include possessing both high tensile strength and large tensile modulus that can be tailored for specific applications. With the perfect blend of lightness and durability, engineering materials that possess a high strength-to-weight ratio are essential for designs where ultimate performance is paramount.

Finding the Right Partner

Gensun is an expert in CNC machining services and material selection. We provide CNC Machining Services that are tailored to your job specifications, with speed and efficiency at a competitive rate. Working hand in hand with our clients, Gensun prides itself on taking their projects from concept through completion.