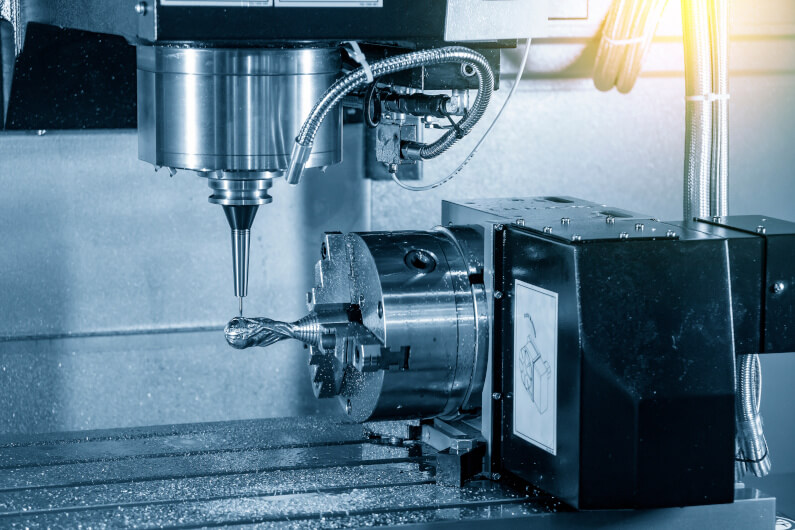

Machine shops contain a diverse collection of equipment for meeting the production needs of designers. This machinery can be used together to create an unlimited number of unique shapes for both simple and complex parts.

Without machining expertise, however, design engineers may not understand the capabilities and limitations offered by different kinds of CNC machining equipment. This can introduce unexpected production inefficiencies and increase manufacturing costs.

This article explains the differences between two types of CNC milling machines, specifically 3-axis and 4-axis CNC milling machines. The biggest difference between these machines is their ability to manipulate parts. The possibilities for more advanced movements mean more capabilities.

By understanding how 4-axis CNC milling is different from 3-axis milling, designers can better anticipate what equipment they will need to efficiently manufacture parts.

What is 3-Axis CNC Machining?

CNC machining almost always relies on a Cartesian coordinate system to define its positioning and movements. This means an x-axis, y-axis, and z-axis. The most basic milling equipment on the market is capable of 3-axis machining along these axes.

This means translation movement, or sliding, in 3 directions only: side to side, front to back, and up or down. We define these directions as the x-axis, y-axis, and z-axis respectively.

While 3-axis CNC machines can combine movement along different axes at the same time to create curved shapes, they have somewhat limited capabilities. Parts with features on multiple sides require manual repositioning and realignment between operations, which slows things down. Repositioning workpieces is simplified and sped up by using a separately designed jig, which may also be essential for features like angled grooves.

More complex features that incorporate curvature outside of a single xy-plane may not be even possible on a 3-axis milling machine. For example, helical grooves or the lobes of a camshaft. This means 3-axis CNC mills are best reserved for simple operations like drilling holes or milling slots.

What is 4-Axis CNC Machining?

A 4-axis CNC mill is capable of all the same movements as a 3-axis milling machine, but adds an additional rotary axis, known as the A-axis. This 4th axis is in line with the x-axis used for side-to-side motion. This means the A-axis allows the workpiece to roll forward or backward from the operator’s perspective.

While most 3-axis mills have a “flat” table for mounting parts, 4-axis CNC machines use either a chuck, a faceplate, or a tombstone fixture block. Chucks and faceplates grip an individual part from the side, which can then be rotated for 360° access to all sides. Tombstones hold multiple components simultaneously for batch production.

The A-axis is useful with either continuous movement for rounded features, or by indexing, which repositions and then fixes the part at a new angle. Either way, the 4th axis adds additional capabilities and improves efficiency on parts that need machining on more than one face.

Is 4-Axis Machining Better?

While a 3-axis CNC machine may be all that’s needed for small, simple machining jobs, a 4-axis CNC is sometimes preferred for three reasons:

- The 4th axis adds the capability for machining more complex features.

- When machining multiple faces, a 4-axis CNC mill improves efficiency by not requiring workers to reposition and realign parts.

- Repositioning parts on a 3-axis CNC can introduce inaccuracies and affect the ability to meet design tolerances.

There are also 5-axis CNC machines available to further increase the allowable complexity of machined parts. Gensun uses a full range of high-precision machining equipment to manufacture the parts you need within tight tolerances. Check out our CNC services page to learn how we can help you bring your next product design to the market.