Are you a product designer looking to turn your product idea into reality, or do you have a part you want to manufacture? If so, you’re likely looking to choose a manufacturing technology to create your parts accurately and precisely.

Computer numerical control (CNC) machines satisfy all of these requirements and more. Not only can these machines create simple and complex parts accurately and precisely, but they are also fast and cost-effective. However, there are several types of CNC machines, each having its unique design and suitability for creating different part features.

In this article, we will talk about ten of the most common types of CNC machines in the manufacturing industry. You’ll learn about how each of these machines operates and the different manufacturing processes and operations they can perform.

What is CNC Technology?

Computer Numerical Control (CNC) describes the idea of automatically controlling machine tools through pre-programmed software and code.

The CNC machining process starts with 3D modeling of the desired part using CAD (Computer-Aided Design) software. Next, the 3D model is loaded into a CAM (Computer-Aided Manufacturing) software, creating a set of computer instructions (G-code) that controls the sequence of movements of the cutting tools on the workpiece.

Now let’s look at the different types of CNC machines and how they differ.

#1 CNC Milling Machines

CNC milling machines (or CNC mills) are the most common type of CNC machines. They feature a multi-blade cutting tool attached to a spindle and made to rotate at high speed against a stationary workpiece. They are ideal for creating cavities, angled cuts, off-center holes, and complex features.

Learn More: What is CNC Milling?

#2 CNC Routers

Image Source: Rickwashburn1, CC BY-SA 4.0, via Wikimedia Commons

CNC routers (or routing machines) are very similar to CNC millsㅡthey use a multi-blade cutting tool that rotates against the workpiece to create desired parts. However, while CNC mills are commonly used for hard metals and industrial-grade materials, CNC routers are better suited for cutting softer and delicate materials like plastics, wood, and foam.

They are ideal for creating panels, plastic prototypes, and molds for injection molding applications.

#3 CNC Lathes

CNC lathes (or turning machines) share similarities with CNC mills and routers; they feature chuck and spindle and rely on CNC technology. However, these machines differ in their working methods, which are exact opposites.

In CNC lathes, the chuck and spindle hold and rotate the workpiece against a stationary cutting tool. These machines usually have a 3-axis configuration and can achieve tolerances as tight as ±4 μm. Thus, they are ideal for machining complex cylindrical shapes.

If your machining project requires high-quality turning processes, including taper turning, knurling, drilling, parting, and grooving, then a CNC lathe machine is the ideal equipment to use. You may also use this machine for reaming, counterboring, spot facing, and thread cutting operations. However, bear in mind that CNC lathes get less accurate as the workpiece gets thicker.

Learn More: What is CNC Turning?

#4 CNC Laser Cutter

CNC laser cutters are similar to CNC mills in the type of shapes or features they can machine. However, they differ from their milling counterparts by performing cutting operations using laser beams.

A laser beam is a column of high-intensity light. When focused on a workpiece, it melts the workpiece till a cut is created. CNC technology controls the sequence of movements of the laser cutting head (and laser beam) till the desired custom part is made.

CNC laser cutters offer a high level of cutting accuracy and are great for cutting a wide range of materials, including metals, plastics, and hardwood. In addition, their extremely high precision makes them ideal for machining your brand name and logo to a CNC milled or turned part.

Learn More: What is a CNC Laser Cutter?

#5 CNC Plasma Cutting Machines

Image Source: Steve Brown Photography, CC BY-SA 3.0, via Wikimedia Commons

CNC plasma cutting machines also offer a high level of cutting accuracy and a wide range of material compatibility, like laser cutters. They only differ from laser cutters by performing cutting operations using a plasma torch.

The plasma torch generates high-powered plasma (or charged gas) capable of reaching temperatures of up to 50000°F. This tremendous amount of heat energy seamlessly cuts through any material so long as it is electrically conductive.

#6 CNC Electrical Discharge Machines (EDM)

CNC Electrical Discharge Machines, also known as spark CNC machines, use electrical sparks from a metal tool to cut the workpiece into the desired shape. Like plasma cutting machines, electric discharge machines also require that the workpiece is electrically conductive. This stringent requirement exists because the metal tool serves as an electrode and can only disintegrate electrically conductive materials.

Electrical discharge machines are ideal for machining micro slots, holes, and angled features in difficult-to-machine metals, such as high-carbon steel and hardened steel.

Learn More: What is EDM?

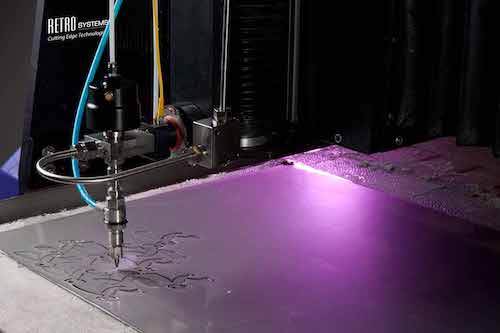

#7 CNC Water Jet Cutters

Image Source: Steve Brown Photography, CC BY 3.0, via Wikimedia Commons

As its name implies, a CNC water jet cutter uses high-pressure jets of water (or a mixture of water and an abrasive substance) to cut through materials. Computer numerical control technology controls the sequence of motion of the water jet to create the desired finished part.

CNC water jet cutters are quite similar to CNC plasma and laser cutters in the sense that they eliminate the need for machine tools. However, unlike CNC plasma and laser cutters, CNC water jet cutters are especially suited for materials with low thermal resistance, like aluminum and plastics. By “low thermal resistance,” we mean the materials are prone to melting when you expose them to high temperatures.

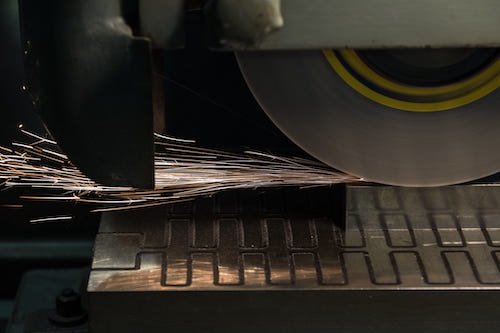

#8 CNC Grinders

CNC grinders (or grinding machines) feature rotating wheels that cut materials from a workpiece to create a product that meets your specification. These machines also feature intelligent thermal control systems that check the temperature of the grinding wheel and compensate for changes that might otherwise affect the accuracy of the machined parts.

All these advantages make CNC grinders ideal for high-precision manufacturing applications. For instance, you can use CNC grinders to create high-quality metal workpieces for transmission shafts, camshafts, and other complex parts that require precise surface finishes.

Learn More: Surface Finish and the Surface Roughness Chart

#9 CNC Drilling Machines

Image Source: Cosme2c, CC BY-SA 3.0, via Wikimedia Commons

CNC drilling machines are quite similar to traditional drilling machinesㅡthey utilize a rotating cutting tool to produce holes in a stationary workpiece. However, because CNC drilling machines rely on CNC technology, they are more accurate and versatile than traditional drilling machines.

For instance, CNC drilling machines can create holes while achieving tolerances as tight as ±0.001mm. They are also compatible with a wide range of materials, including metals, plastics, and wood. In addition, recent CNC drilling machine technologies feature a tool turretㅡwhich accepts multiple drill bits and allows you to quickly shuffle between the bits during manufacturing.

You should opt for CNC drilling machines if you’re looking to fabricate hubs, gear blanks, and machined shafts.

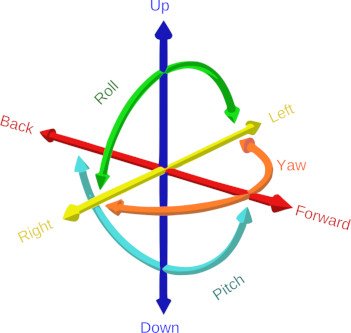

#10 6-axis CNC Machines

Image Source: GregorDS, CC BY-SA 4.0, via Wikimedia Commons

The axis of a CNC machine describes the number of independent directions that the CNC cutting tool (or workpiece) can move to create a machined part. For instance, a 3-axis CNC machine typically operates along the X-axis (vertical), Y-axis (horizontal), and Z-axis (depth) to machine a workpiece and create a finished part.

However, CNC machine technology has advanced to include 6-axis capabilities in recent years. 6-axis CNC machines combine the three-axis linear movement of 3-axis machines with rotation about the X-, Y-, and Z-axes. This ensures that the cutting tool remains perpendicular to the material surface on multiple planes, allowing you to create complex parts.

6-axis machines can fabricate pretty much any complex design, so long as the machinist is skilled in CNC parts manufacturing.

CNC Machining High-Quality Parts: Gensun Can Help

Now that you know the different CNC machine types and their capabilities, you’d agree that CNC machines can fabricate pretty much any part, feature, or product. However, the success of your manufacturing project also depends on the machine shop and machinists creating your products.

Gensun Precision Machining is a leading provider of CNC machining services across Asia. Not only do we have a wide variety of CNC machine types, but we also have highly experienced engineers and machinists capable of getting your product done right.

Learn more about our CNC machining services.

Note: This article was originally published in June of 2021 and was updated in May of 2022