Are you considering different manufacturing processes to make your part? Would you like to learn more about CNC turning to decide if it’s appropriate for your situation?

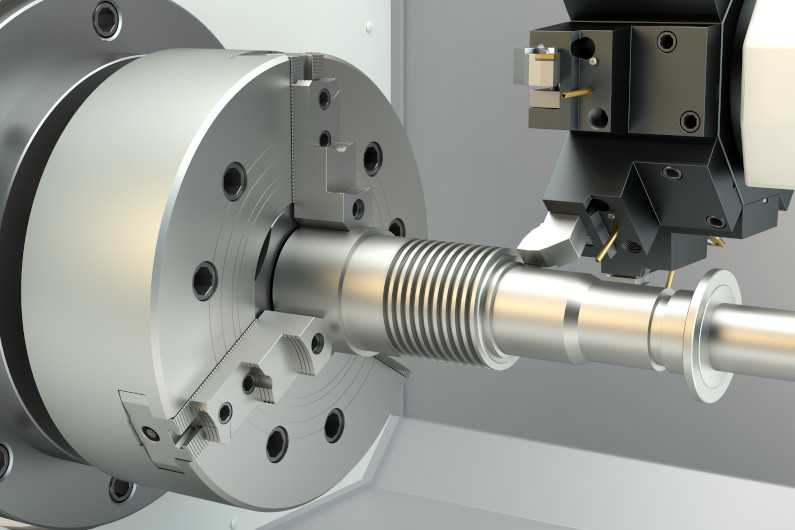

CNC turning is a CNC process where a cutting tool, a typically non-rotating component of the lathe or turning center, removes material from a rotating rigid material. It produces different shapes and sizes depending on the turning operations used.

You may be wondering what a lathe or turning center is, what shapes you can make by this process, or how it compares to CNC milling. Here, we will answer these questions and help you understand if CNC turning is right for your project.

What Does CNC Turning Mean?

The name CNC Turning can be broken down into two parts:

- “CNC” stands for computer numerical control and represents the automation of a machining process.

- “Turning” is a process where the workpiece rotates while a single-point cutting tool removes material.

This is an industrial machining process controlled by a computer and carried out on equipment capable of turning: a lathe or a turning center. The process can take place with the axis of rotation in the horizontal or vertical orientation. The latter being used primarily for workpieces with a large radius relative to their length.

Is the Workpiece The Only Part That Moves?

Although the workpiece is generally the only object rotating, the cutting tool can move too! Tooling can move on 1, 2, or even up to 5 axes to produce precision shapes. Now, you can imagine all the shapes you can achieve using a block of metal, wood, or plastic.

CNC turning is a widespread manufacturing method, so it isn’t hard to spot some everyday objects we use that are manufactured using this process. Even the device you are using to read this blog has screws or bolts and nuts produced by a CNC turning machine, not to mention applications as advanced as aerospace or automotive parts. But, how are all those made?

What Shapes Can CNC Turning Make?

Various parts made by CNC turning

Turning is a versatile machining process capable of making a wide range of profiles depending on the turning process used. The functionality of lathes and turning centers allows for straight turning, taper turning, external grooving, threading, knurling, boring, and drilling.

Generally, lathes are limited to simpler turning operations, like straight turning, external grooving, threading, and boring operations. The tool turret on turning centers allows the turning center to complete all the operations of a lathe as well as more complex operations, such as drilling off the axis of rotation.

CNC turning can produce a wide range of shapes with axial symmetry, like cones, cylinders, disks, or a combination of those shapes. Some turning centers are even capable of polygonal turning, using special rotating tools to create shapes like a hexagon along the axis of rotation.

What Do You Need to Make A CNC Turned Part?

A CNC turned part

Though this is a complex process, we will simplify it for you with just three simple ingredients: the design of the piece, the cutting speed-to-feed ratio, and the raw material. So, let’s start!

The Design of Your Piece

The very first step is to translate your design into the CNC turning machine language. No worries, we are not talking about advanced programming. Probably, you have already made some drawings of your design. Great! You may want to consider capturing those designs electronically in software like AutoCAD or SolidWorks.

Once you have your electronic design, it is a piece of cake! You only need to convert your drawing, saved as a CAD file by default, into the proper format, the CAM file. Actually, software tools such as AutoCAD and SolidWorks can export the drawing with this format using the “export as” option.

Cutting Speed vs. Feed Rate

Now comes the action! In the turning process, there are two variables you need to keep in mind. The first is the turning speed, which is the velocity of the rotation of the workpiece. The second is the feed rate, which is the velocity at which the cutting tool moves along the rotating workpiece.

These values must be determined by an expert as improper estimations will affect your results, and with some materials, this could cause an uneven finish or irreparable damage to the workpiece.

That said, lower turning speeds and a higher feed rate are generally used for “roughing” out the shape. Then a high turning speed combined with a lower feed rate is used to create a smooth finish and to create parts that meet precise tolerance requirements.

Raw Material

The raw material is a crucial ingredient! Undoubtedly, the type of material used determines the properties of the resulting part. The same piece obtained from wood, plastic, or metal will differ in functionality and even the roughness or smoothness of the finished surface. For more information on the types of materials you can use, check out our blog post on materials for CNC machining.

The size, weight, and shape of the workpiece are also critical because they affect the balance of the workpiece and the size of the lathe or turning center required. An unbalanced workpiece will not create precise final results!

CNC Turning vs. CNC Milling: How do They Compare?

When it comes to choosing the right CNC machining process for your project, understanding the differences between CNC turning and CNC milling is essential. Both processes offer unique advantages and capabilities that can significantly impact the final outcome of your machined part.

Let’s dive deeper into the key differences between CNC turning and CNC milling and provide a guideline to help you determine the right process for your part.

Workpiece Motion: The Core Difference

The main difference between CNC turning and CNC milling lies in the workpiece motion. In CNC turning, the workpiece rotates while the cutting tool remains stationary. This process allows for the creation of axially symmetric parts with incredible precision and smooth finishes.

CNC milling involves a stationary workpiece while the cutting tool moves in multiple axes. This process enables the production of parts with complex geometries and intricate details that would be impossible to achieve with turning alone.

Versatility in Part Geometry

The versatility of CNC turning and CNC milling differs significantly, particularly when it comes to part geometry. While CNC turning excels at creating parts with axial symmetry, such as cylinders, cones, and disks, CNC milling offers a broader range of possibilities.

With the ability to produce complex shapes, pockets, slots, and intricate 3D features, CNC milling is the go-to option for parts requiring more elaborate designs.

Achieving the Perfect Surface Finish

Both CNC turning and CNC milling can achieve high-quality surface finishes, but the nature of these finishes can vary. The continuous rotation of the workpiece in CNC turning typically results in a smoother, more polished finish.

In contrast, CNC milling may leave a pattern of tool marks, depending on the milling strategy and cutting tool used. However, with the right tooling and parameters, CNC milling can also achieve excellent surface finishes.

Tooling and Setup: Time and Cost Considerations

When it comes to tooling and setup, CNC turning generally has the upper hand. Fewer tools are required, and the setup process is often quicker and more straightforward. In comparison, CNC milling may necessitate multiple tools to achieve the desired complex geometries, which can increase both setup time and cost.

This is an important consideration when evaluating the most efficient and cost-effective manufacturing process for your part.

Is CNC Turning the Right Choice for Your Part?

CNC turning is a cornerstone in the manufacturing industry. Let’s discuss how you can determine if you should use this process for your part.

Design Considerations for CNC Turning

Part Geometry: CNC turning is particularly well-suited for parts with a cylindrical or rotational symmetry. Common examples include shafts, gears, and pulleys. If your product has complex 3D geometries or features that cannot be achieved through simple rotational movements, you may need to consider other manufacturing methods such as CNC milling, 3D printing, or injection molding.

Material Properties: The material properties of your product can influence its compatibility with CNC turning. The process is best suited for materials that are easy to machine, such as aluminum, brass, and plastics. However, hard or abrasive materials like stainless steel or titanium may require specialized tooling or result in slower production rates and increased tool wear

It is essential to carefully evaluate the material properties of your product to determine if CNC turning is the most cost-effective and efficient manufacturing method.

Tolerance Requirements: CNC turning can achieve high precision and tight tolerances on the order of +/- 0.001 inches (0.025mm) or better, depending on the machine and material used. If your product requires tighter tolerances or complex surface finishes, you may need to consider alternative manufacturing methods or secondary processes such as grinding or polishing.

Factors That Might Make CNC Turning Unsuitable for Your Product

Complex Geometries: As mentioned earlier, CNC turning is limited to parts with rotational symmetry. If your product has intricate or non-rotational features, you may need to consider alternative manufacturing methods.

Size Limitations: CNC turning machines have size limitations due to their workholding and tooling capabilities. If your product is too large or heavy for the machine’s capacity, you may need to explore other manufacturing processes.

High Production Volumes: While CNC turning is great for low to medium production volumes, it may not be cost-effective for high-volume production. For large-scale manufacturing, processes like die casting or injection molding may be more suitable.

Alternative Manufacturing Methods

die casting mold

CNC Milling: This process is ideal for producing parts with complex geometries and features that are not achievable through turning. CNC milling machines can handle a wide range of materials and are capable of achieving tight tolerances.

Injection Molding: Suitable for high-volume production of plastic parts, injection molding is a cost-effective method for manufacturing complex geometries that cannot be produced through CNC turning.

Die Casting: This process is suitable for producing large quantities of metal parts with tight tolerances and complex geometries. Die casting is particularly useful for producing parts made from materials that are difficult to machine, such as zinc or magnesium alloys.

If your design is axially symmetric, this could be the right manufacturing process for you to create precision parts, either for mass production or in small batches. Nevertheless, if you feel that your designed parts are too large, heavy, non-symmetrical, or have other complex geometries, you may want to consider another manufacturing process, such as CNC milling or 3D printing.

Work With Us

If you are considering using CNC turning, you should check out our turning services page or reach out to one of our service experts to learn more about your options for products manufactured by our efficient, high-precision CNC turning process.