If you’ve recently come up with a product design, then you’ve probably answered some common questions your manufacturer might have for you. For instance, what are your choice of material, the dimensions, strength, and tolerance requirements, and how many units are you looking to produce?

However, even after you answer all of these questions, you can’t rule out the possibility of failure when you begin to mass-produce your final product. One way top-tier product designers mitigate these risks is by rapid prototyping. This article explains rapid prototyping and provides helpful tips to help you choose the ideal method.

What is Rapid Prototyping?

Rapid prototyping involves manufacturing sample parts of your product to test for component fit, function, manufacturability, appearance, and strength. It allows you to spot design flaws early during product development so you can take measures to correct them. However, because of the several rapid prototyping technologies available today, you might be confused about choosing the ideal rapid prototyping technology and method for your project.

Choosing the Ideal Rapid Prototyping Method

Three commonly used methods for rapid prototyping include:

- 3D printing

- Injection molding

- CNC machining

#1 3D Printing

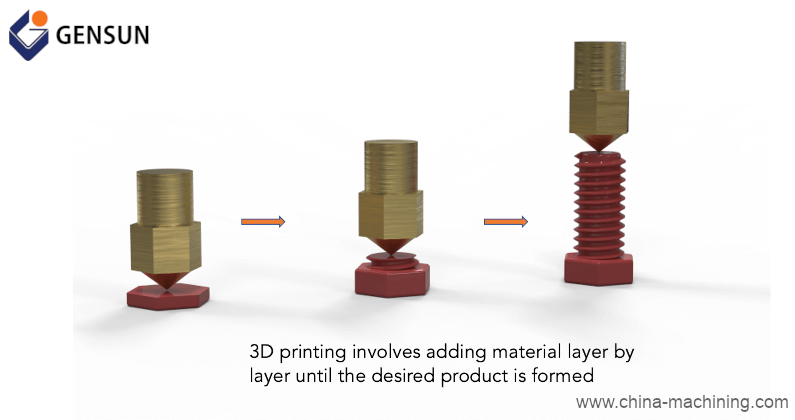

3D printing is an additive manufacturing process ㅡ which means it involves adding portions of materials in layers to form the desired prototype. It is the most common method for rapid prototyping because of its high accuracy, material compatibility, and low cost (especially for a low volume of parts).

Figure 1: The 3D printing process

However, 3D printing technologies come in several types, each having its capability and suitability for different prototyping needs. For instance, three commonly used 3D printing technologies include:

- Fused Deposition Modeling (FDM)

- Stereolithography

- Selective Laser Sintering (SLS)

Fused Deposition Modeling

Fused Deposition Modelling (FDM) is the most popular 3D printing method for rapid prototyping. FDM 3D printers work by extruding thermoplastic filaments (like PLA and ABS) layer by layer through a heated nozzle. It typically has a maximum build size of 320 x 132 x 154 mm and is suitable for creating prototypes that you’ll subject to form fit testing.

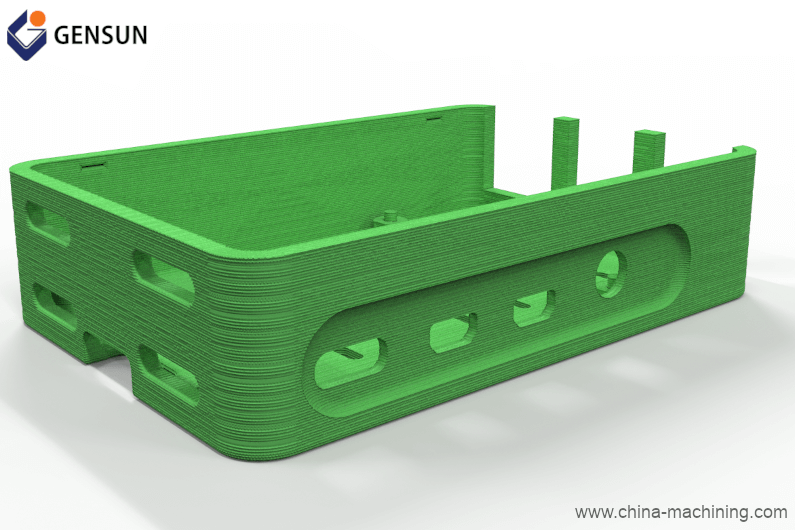

For instance, Figure 2 shows the prototype of a Raspberry Pi casing created using an FDM 3D printer to be subjected to form fit testing.

Figure 2: FDM-printed Raspberry Pi casing

However, the size of the extrusion nozzle defines the resolution of an FDM-printed part. Therefore, FDM might not be an ideal method to create prototype parts requiring intricate details.

Stereolithography (SLA)

A stereolithography 3D printer creates prototypes using a highly-precise laser. This laser cures liquid resin, eliminating the low-resolution challenge common in FDM 3D printing. As a result, SLA 3D printers can achieve higher accuracy and finer details than FDM 3D printers.

You should opt for SLA 3D printing if you’re looking to create detailed visual prototypes requiring tight tolerances, ultimate precision, accuracy, and a smooth surface finish. However, keep in mind that SLA 3D printing typically has a maximum build size of 145 x 145 x 175 mm.

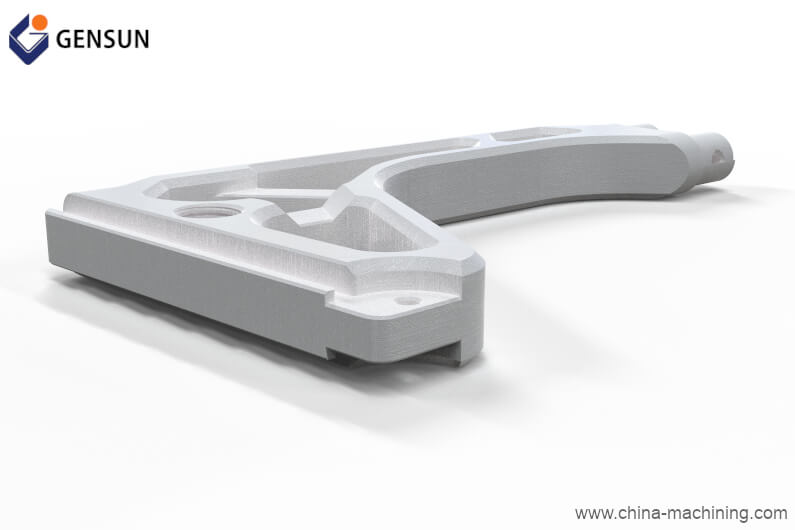

Figure 3: Prototype created using an SLA 3D printer

Selective Laser Sintering (SLS)

In Selective Laser Sintering (SLS), lasers are used to sinter powdered material (usually polyamide or nylon) in layers to create the desired prototype. SLS 3D printing is great for creating fully functional prototypes that require good mechanical properties. It offers a greater build size (300 x 300 x 300 mm) than SLA 3D printing but produces parts with a rougher surface finish.

Figure 4: Prototype created using an SLS 3D printer

#2 Injection Molding

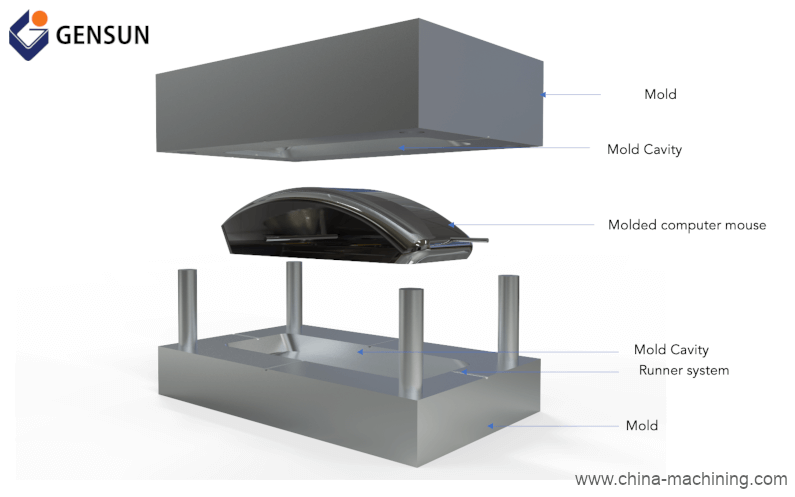

Injection molding is a manufacturing method that involves using molds to create prototypes. To create prototypes using an injection molding machine, your manufacturer will first create a mold in the shape of your desired product. Next, the manufacturer heats up a thermoplastic polymer, changing it to molten fluid. This fluid is then injected into the mold cavity through a runner system to form the desired shape.

Figure 5: Injection molding process

Injection molding is compatible with many materials (thermoplastics, metals, and liquid silicone rubber) and can create complex product designs. However, it is usually ideal for producing several replicas of a prototype, especially when you need to perform a series of tests on these prototypes.

For instance, consider Figure 6, which shows a computer mouse prototype (made of silicone rubber) without any electrical system.

Figure 6: Computer mouse prototype

In this scenario, you can create several units of this prototype to test for ergonomics ㅡ which means you want to test how this computer mouse affects users’ ability to work comfortably and effectively. For instance, you can determine how this mouse design fits your user’s hand or how it restricts arm movement or blood circulation.

The results you get from this test can help you take product design measures to reduce the risks of mouse arm syndrome and carpal tunnel.

#3 CNC Machining

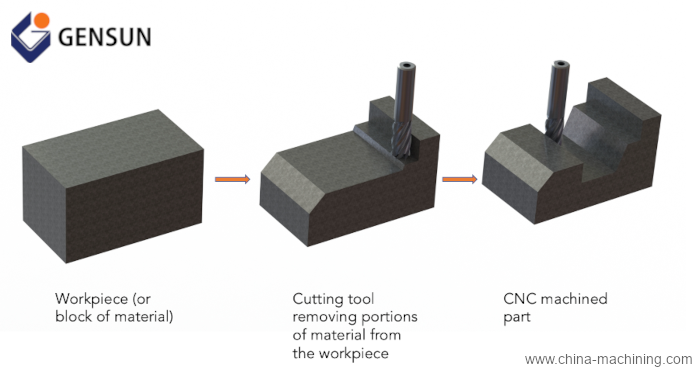

CNC machining is a subtractive manufacturing method ㅡ which means it creates the desired prototype by removing portions of material from a workpiece using cutting tools. Computer numerical control (CNC) technology automates the cutting tool’s and workpiece’s sequence of movement to create your prototypes.

Figure 7: The CNC Machining Process

CNC machining is generally the best rapid prototyping method for metal parts, especially when you need to create highly accurate functional prototype products (like jigs and fixtures and components for end-use applications). For instance, CNC machines can achieve tolerances as small as 0.004 mm and mechanical strength of up to 136 MPa. However, the subtractive nature of CNC machining means some features might be challenging to fabricate (for instance, undercuts).

Learn more: Understand How to Design for CNC Machining.

Rapid Prototyping Services: Gensun Can Help

3D printing, injection molding, and CNC machining are capable of creating a wide range of product design prototypes quickly. However, your rapid prototyping project’s success primarily depends on the machine shop you work with.

Gensun Precision Machining is a leading provider of rapid prototyping services across Asia. Not only do we have 3D printing, injection molding, and CNC machining capabilities, but we also have highly trained engineers and quality control experts who work together to get your product done right.

Learn more about our rapid prototyping services.