Since the beginning of the first industrial revolution, product design requirements have become more stringent. For instance, in the 1770s, you could fabricate pretty much anything using conventional hand tools. However, turning a product idea into products today requires best-in-class manufacturing technologies and highly qualified machinists.

One of the processes paving the way for machinists to meet today’s demanding product design requirements is called plain milling.

But what exactly is plain milling, how does it work, and what are its capabilities in today’s manufacturing industry? In this article, we’ll answer all of these questions and more. We’ll explain everything you need to know about this fascinating manufacturing process.

What is Plain Milling?

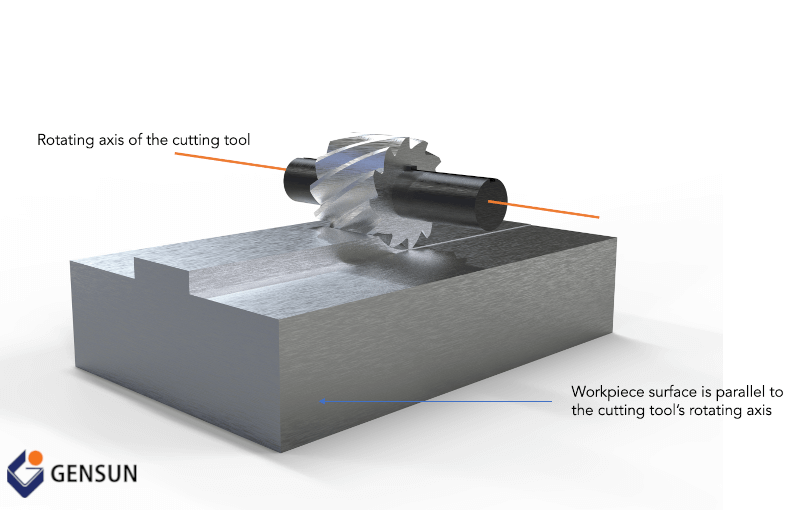

Plain milling (also known as slab milling) is a subtractive manufacturing processㅡwhich means it involves removing portions of material from a workpiece to form the desired product. However, unlike the conventional subtractive manufacturing process, the process requires that the rotating axis of the cutting tool is parallel to the surface of the workpiece, as shown below:

Figure 1: The plain milling process

In plain milling, the workpiece is usually fixed on a worktable. This worktable moves and feeds the workpiece against the cutter, allowing machinists to create a plain, flat, and horizontal surface parallel to the axis of the cutting tool.

Types of Plain Milling Cutters

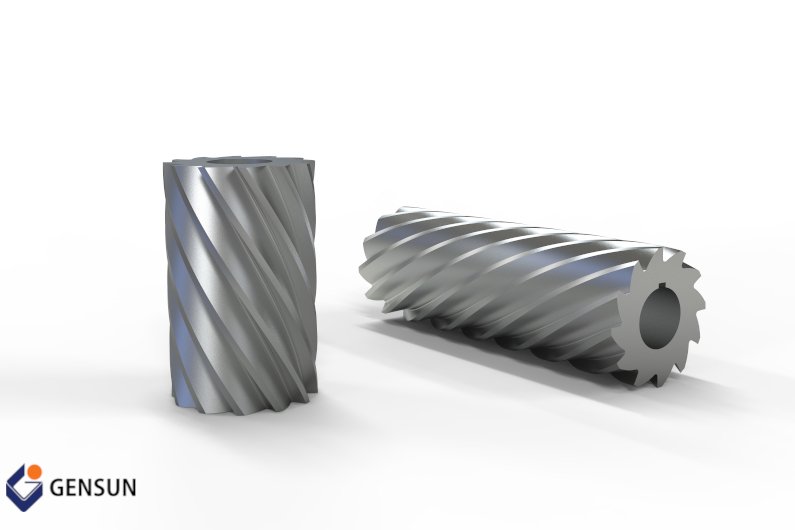

Slab milling cutters have a cylindrical geometry with cutting teeth on the periphery of the cutter. They are categorized into:

- Light duty plain milling cutters

- Heavy duty plain milling cutters

Figure 2: Plain milling cutters

Light-duty Cutters

As their name implies, light-duty cutters are used for light-duty cutting operations. These cutters usually have several helical teeth with a helix angle that is less than 25°. This unique design makes light-duty cutters ideal in applications requiring large portions of material removal to form desired products.

Heavy-duty Cutters

The heavy-duty cutters have fewer teeth and a greater helix angle (between 25° to 45°) than the light-duty cutters. As a result, they are ideal for heavy-duty machining and cutting operations that require a smooth surface finish.

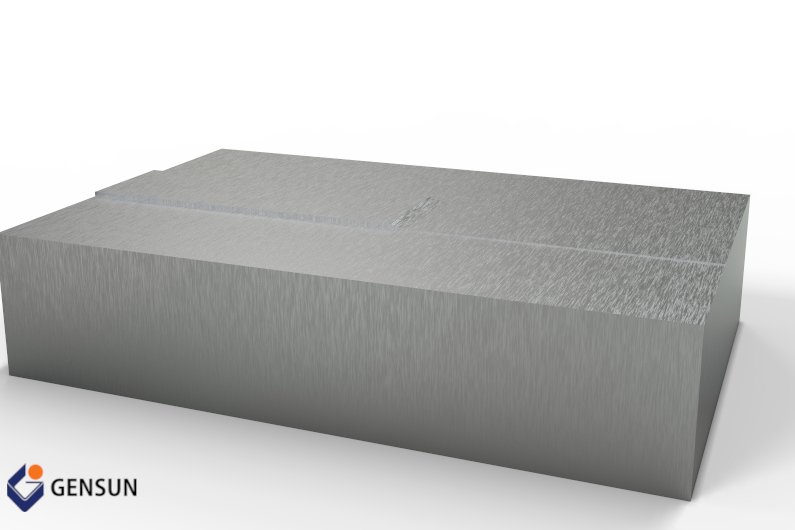

Figure 3: Heavy-duty cutters are ideal for applications requiring a smooth surface finish.

While light-duty and heavy-duty milling cutters can fabricate a broad range of features, machinists also pay close attention to the size of the cutters during machining. For instance, machinists usually achieve deeper cuts using narrow cutters. In contrast, wide cutters are better suited for machining workpieces with large surface areas, as these cutters reduce the number of traverses required to create a feature.

Tips for Slab Milling

Top-tier machinists and machine shops adhere to the following tips during the plain milling process:

- Maintain a sufficient clearance between the milling machine spindle and cutter as this reduces torque and the possibility of vibration during machining.

- Choose the ideal cutting speeds and cutter material for the manufacturing process. For instance, carbon steel cutters are ideal for low-speed milling operations, while carbide-tipped cutters are better suited for high-speed milling machine operations.

- Use water-based cutting fluids (or coolant oils) on the cutter in applications where the cutter runs at very high speeds. These oils have good thermal resistance, allowing them to dissipate heat and prolong the life of the plain milling cutter.

- Use cutting fluids with good lubricating properties for surface finishing operations. These cutting fluids lubricate the cutter teeth and remove metal chips, eliminating the possibility of marring the workpiece surface.

- Use computer numerical control (CNC) technology to automate the movement of the cutting tool and workpiece to create the desired part accurately and precisely.

Learn more: Understanding the CNC Machining Process.

Plain Milling: Gensun Can Help

Gensun is a leading provider of machining services across Asia. We’ve been in business for nearly two decades, providing high-quality manufacturing services to our customers across several industries.

Learn more about our CNC machining services.