Have you recently come up with a custom part design, or do you need to manufacture a part with special requirements? If so, the next steps are to hire a manufacturer, send over your 3D computer-aided design (CAD) file, receive a fair product quote, and manufacture your product, right? Not exactly.

The truth is that a lot can go wrong if your product is not correctly designed for manufacturing from the onset. For instance, you might incur huge manufacturing costs or defects that render your product useless. Therefore, there are several things and design tips that you must first understand before creating your 3D CAD and reaching out to that manufacturer.

This article covers all of these and more. It will serve as a guide to help you prepare for your project quote.

Understand the Manufacturing Process

Understanding the manufacturing technology and process a manufacturer will use to fabricate your product helps you create product designs you can easily fabricate with that technology. For instance, CNC machining and 3D printing ㅡ two of the most popular manufacturing methods today ㅡ have different modes of operation and suitability for different custom product design scenarios.

CNC machining is a subtractive manufacturing process. That means it involves removing portions of material from a workpiece (using cutting tools) until the desired product is formed. It utilizes computer numerical control (CNC) technology to automate the movement of the cutting tools and workpiece to create the desired product. In contrast, 3D printing is an additive manufacturing process. It involves adding portions of material layer by layer until the desired product is formed.

The CNC machining process is ideal for creating complex custom product designs featuring angled cuts, cavities, off-center holes, and other complex features. While 3D printers can equally create these parts, you have limited material options (plastics and a few metals). Therefore, choosing 3D printing over CNC machining makes sense for certain plastic prototypes or complex parts.

Learn more: CNC Machining vs. 3D Printing

Some Design Guidelines for Custom CNC Machining

Here are some helpful design guidelines to help you achieve high-quality parts and reduce your manufacturing costs.

#1 Cavities

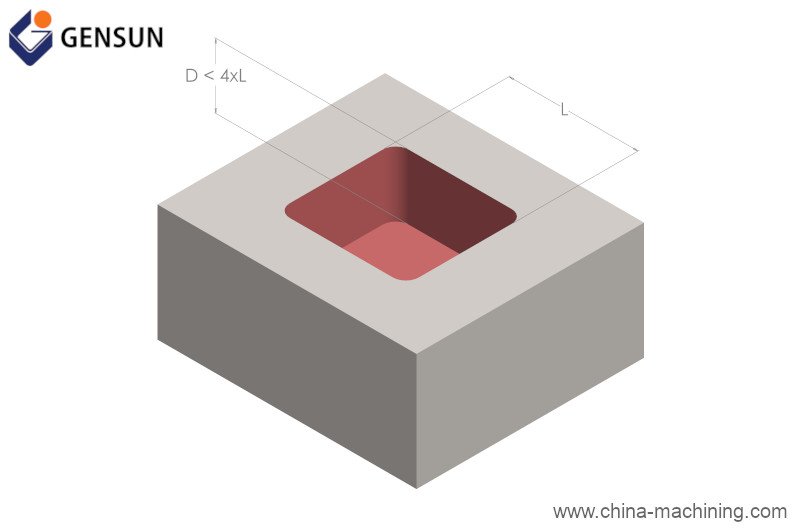

You should design cavities and pockets to have a depth that is less than four times the cavity width. This is because end mill tools have limited cutting length, so you might experience tool deflection and vibration when fabricating cavities with a smaller depth-to-width ratio.

Figure 1: Designing cavities

However, if your product design requires a larger depth-to-width ratio, you will need specialty cutting tools, which might incur additional manufacturing costs.

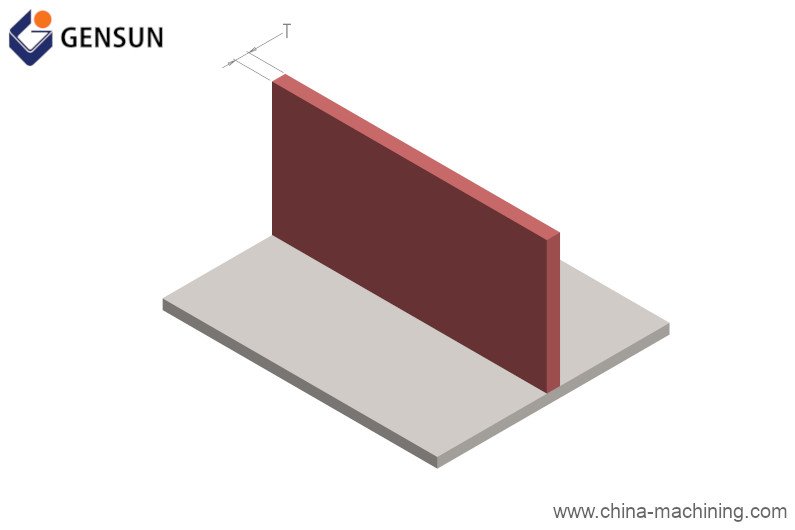

#2 Wall Thickness

Thin walls are prone to vibration during CNC machining, which lowers machined parts’ achievable tolerance and accuracy. Therefore, as a rule, you should design metal parts to have a minimum wall thickness of 0.8 mm, while plastic parts should have a minimum wall thickness of 1.5 mm.

Figure 2: Wall thickness requirements for metal and plastic parts

It’s possible to achieve thinner walls, but it usually comes with additional manufacturing costs.

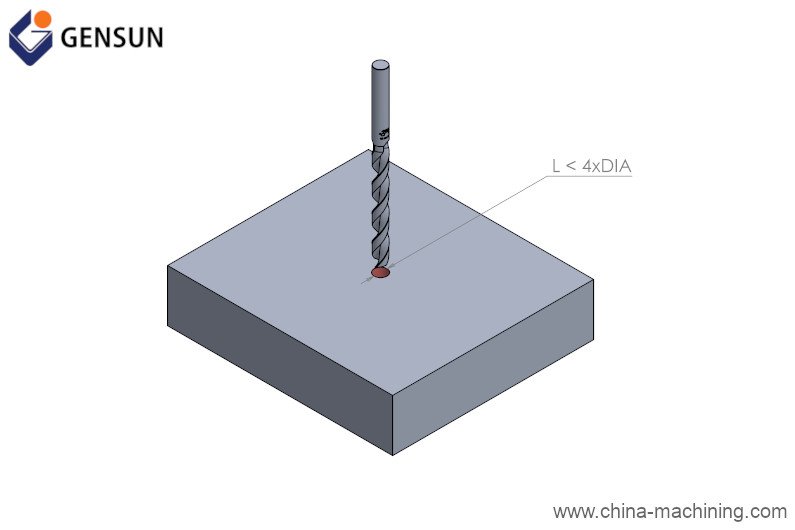

#3 Holes

You should design holes to have standard diameters. This allows you to use standard drill bit sizes to create these holes and eliminates the need for specialty end mill tools. We also recommend that the depth of the hole is less than four times the end mill’s nominal diameter to minimize tool deflection.

Figure 3: Designing holes

#4 Tolerances

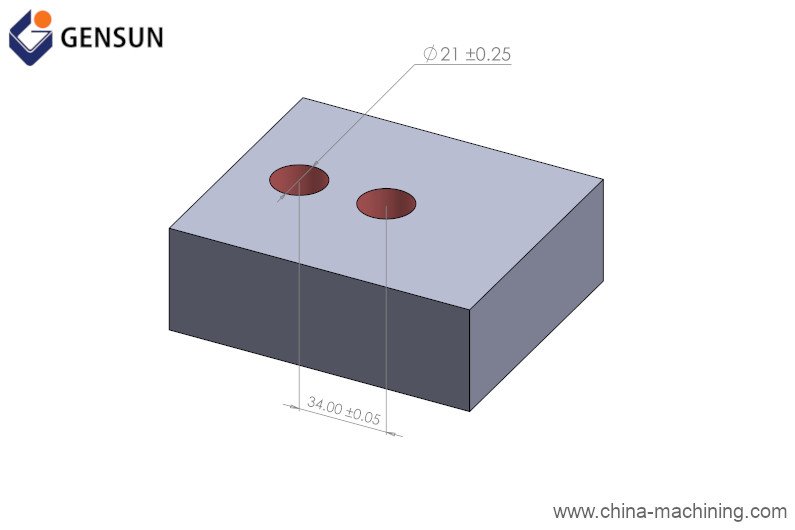

Tolerance is the allowable amount of variation in the size of a machined part that will still allow for it to function properly.

Product designers usually specify tolerances to manufacturers by stating the permissible limits of variation in a physical dimension. You can specify tolerances using the “±” symbol (pronounced “plus or minus”) and accompanied by a value, for example, ±0.05 mm. For instance, say you plan to fabricate a part with two holes (having a diameter of 21 ±0.25 mm), as shown in Figure 4.

Figure 4: Engineering tolerance

In such a scenario, it simply means you permit a deviation of 0.25 mm extra (or less) than your standard diameter value. So, if your manufacturer fabricates a hole with a diameter of 21.25 mm or 20.75 mm, it won’t affect the proper function of your part.

CNC machines are among the most accurate manufacturing technologies, capable of achieving tight tolerances of up to ±0.04 mm. However, keep in mind that tighter tolerance requirements typically result in higher manufacturing costs.

Choose the Ideal Surface Finish

Although the CNC machining process is subtractive, it does a great job of producing parts with excellent surface finishes. The “as-machined” surface finish refers to machined parts coming straight from the CNC machines. These parts retain the accuracy of the manufacturing process and require no additional costs.

Figure 5: As-machined milled part

If your parts require additional post-processing options like anodizing or powder coating, then you can expect a higher project quote from your manufacturer.

Figure 6: Parts with anodized aluminum finish

Parts with powder coated finish

Learn more: Anodized Aluminum Finishes.

Custom CNC Machining: Gensun Can Help

Now that you know a little bit more about custom machining and product design tips, you’d probably agree that your project quote and product development success depends on your product design. That’s why you must work with a manufacturer that looks at your product design and advises you on what’s best for you.

Gensun Precision Machining is a leading provider of custom CNC machining services across Asia. We have a team of highly qualified engineers, technicians, and quality control experts capable of getting your product done right. We keep our customers’ best interests in mind, so use our quoting tool to upload your 3D CAD files, request a quote, and discuss your manufacturing project with our highly qualified engineers.

Learn more about our high-quality CNC machining services.

Note: This article was originally published in Feb 2021 and updated in May 2022