Are you a product designer looking to create prototypes or undergo mass production? If so, you will likely be at a crossroads when choosing between CNC machining and 3D printing to make your products.

CNC machining and 3D printingㅡtwo of the most popular manufacturing methods todayㅡcan fabricate almost any product design you come up with. However, each method has its unique mode of operation, advantages, and capability, making them ideal for different engineering design scenarios.

This article will cover some key areas you need to evaluate before choosing CNC machining or 3D printing for your product development project. In addition, we will provide helpful information about each process, manufacturable features, material suitability, and post-processing options.

Comparing the Processes: CNC Machining vs. 3D Printing

CNC machining and 3D printing are quite similar in operation: they convert a 3D CAD (computer-aided design) model to a set of computer instructions to fabricate parts autonomously. However, these manufacturing processes differ in how they fabricate parts.

CNC Machining

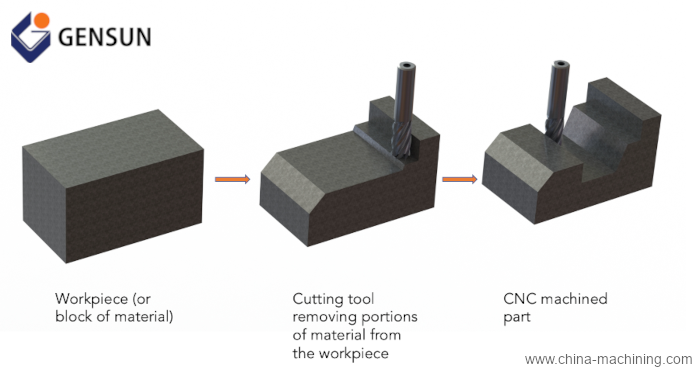

CNC machining is a subtractive manufacturing method. It involves removing portions of material from a block (or workpiece) to create the desired part using cutting tools. Computer Numerical Control (CNC) technology controls the sequence of motion of the cutting tool (and workpiece) to create the desired part.

Figure 1: CNC Machining Process

3D Printing

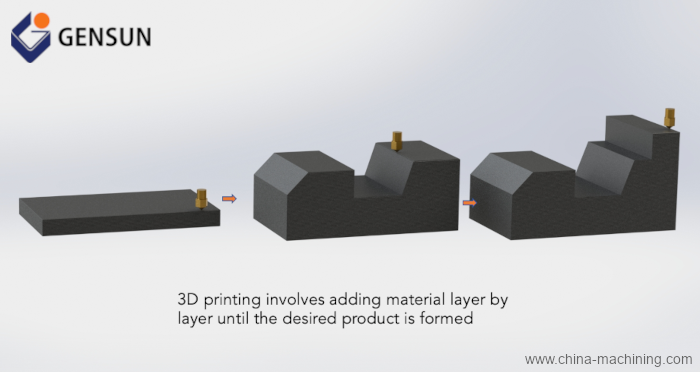

3D printing is an additive manufacturing method. It involves adding materials layer by layer to form the desired product. The process requires no special tooling or fixtures.

Figure 2: 3D Printing Process

Geometry, Minimum Feature Size, and Cost Differences

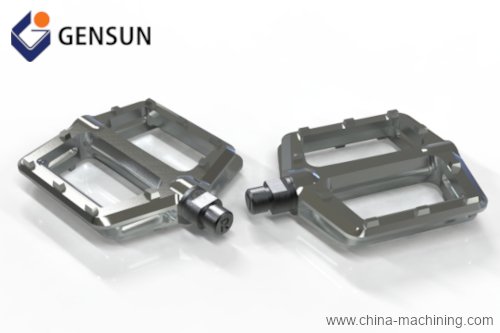

The subtractive nature of CNC machining makes it possible to create a broad range of complex geometries with a minimum feature size of 1 mm. For instance, CNC milling machines are ideal for creating holes, angled cuts, and cavities, while CNC lathes are better suited for complex cylindrical shapes.

Figure 3: Rendering of a CNC milled part

However, you might find it challenging to create hidden features and undercuts using CNC machines.

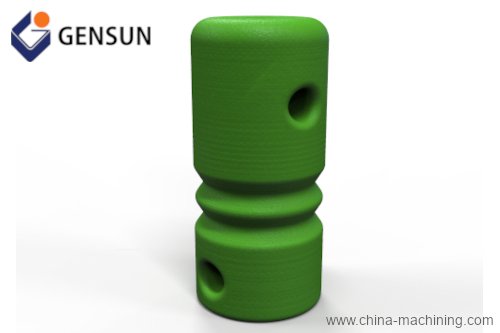

3D printers eliminate the geometry challenge and limitation in CNC machining, allowing you to fabricate complex geometries. However, most 3D printers have minimum feature sizes ranging between 0.25 mm and 0.8 mm and incur substantial manufacturing costs and lead time, especially for large volume parts.

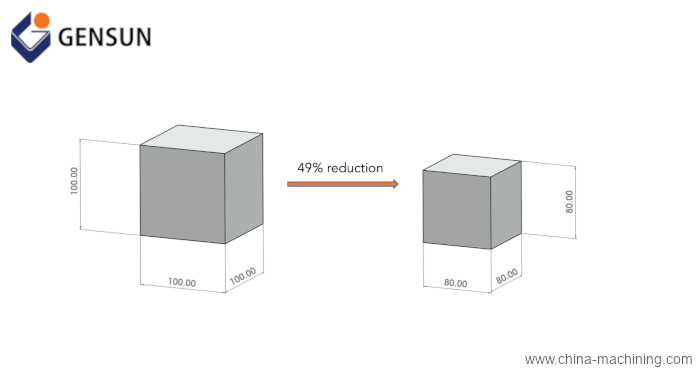

What’s more, slight variations in your product’s size can significantly increase your 3D printing manufacturing costs.

For instance, consider the 3D CAD model of a 100x100x100 mm cube shown in Figure 4. You’d be surprised to know that this cube has double the volume of an 80x80x80 mm cube. As a result, if you decide to 3D print this large volume part, you can expect to use more raw materials and pay twice as much as you would for the smaller cube.

Figure 4: Variation in product size can significantly increase your 3D printing manufacturing costs.

Material Options Available

CNC machines are compatible with a wide range of materials, including metals, plastics, wood, and composites, so long as these materials are available in blocks. For instance, commonly used materials for CNC machining include aluminum, stainless steel, brass, titanium, zinc alloy, polycarbonate acrylic, polypropylene, and PEEK.

Figure 5: Rendering of a CNC machined aluminum part

3D printers are also compatible with various materials but are more commonly used for plastics (like ABS, nylon, PLA, ULTEM, and PEEK), ceramics, and photopolymers. You can also 3D print metals like aluminum, titanium, and superalloys, but keep in mind that 3D printed metals don’t come off the line cheap.

Figure 6: Rendering of a 3D printed plastic

Differences in Surface Finish

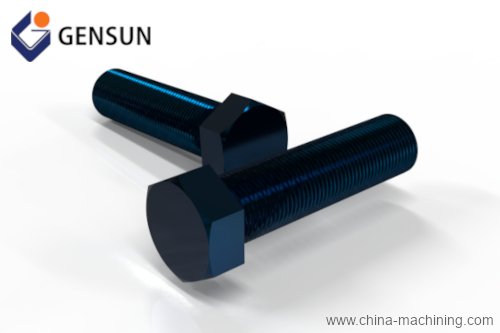

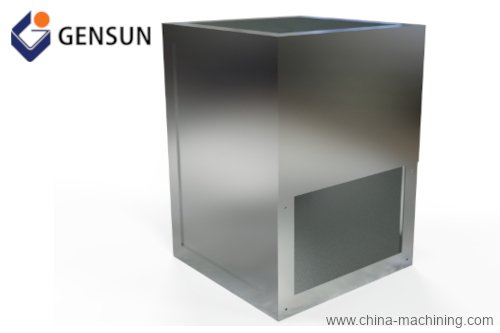

CNC machines and 3D printers can produce parts with extremely smooth surfaces. However, if your parts require exceptional smoothness to mate with other parts, you should consider using CNC machines to fabricate them. CNC machines’ have a great range of control, allowing you to achieve tight tolerances and a higher degree of surface quality.

Nevertheless, CNC machining and 3D printing offer a broad range of surface finishing options. For instance, with CNC machined parts, you can anodize, powder coat, bead blast, and passivate them. Likewise, surface finish options for 3D printed parts include plating, bead blasting, and heat treatments to strengthen the product.

Figure 7: Rendering of an anodized aluminum part

Figure 8: Rendering of a CNC machined part with powder coated finishing

Learn more: Surface Finish and the Surface Roughness Chart

3D Printing vs. CNC Machining: How To Choose the Ideal Method

As we’ve discussed, CNC machining and 3D printing can both fabricate many types of parts.

However, as we always tell our customers at Gensun, there is no perfect, one-size-fits-all manufacturing method. The ideal method primarily depends on your product design, geometry, tolerances, and surface finish requirements. We recommend that you work with a top machine shop with engineers capable of discussing your application needs with you.

Gensun Precision Machining is a leading provider of CNC machining and 3D printing services in Asia. We have a team of highly experienced engineers and machinists, and state-of-the-art manufacturing technologies to get your product done right.

Learn more about our CNC machining and 3D printing services.

Note: This article was originally published in June of 2021 and updated in May of 2022