Plastics’ versatility and numerous advantages make them some of the most important engineering materials today. BMW saved up to 100 kg in weight after ditching metals and relying on thermoplastics and composites for the rear boot lid and front wings of its 6-Series Coupe. Without a doubt, BMW couldn’t have taken this bold step without ever building prototypes and performing tests on them.

So, let’s say you’ve got a big idea and created the design for a new product or part. You should proceed to create plastic prototypes using any machining method, right? Wrong! BMW might not tell you, but your project’s success still largely depends on the machining method you use to create these parts and the third-party manufacturer you choose.

This article covers different methods for creating plastic prototypes, particularly CNC machining. It will help you to decide on the best plan for your project.

Why Would You CNC Machine Your Plastic Prototypes?

CNC machining has numerous advantages, and here are four scenarios that would warrant CNC plastic machining.

Scenario No 1: Your Plastic Prototype Design Features Tiny Details

Do you have a design that features patterns with small radii and requires tight tolerances? Then CNC machining is probably well-suited for your project. A CNC milling machine can achieve radii as small as R0.05 mm and tolerances as tight as 4 μm.

Scenario No 2: You Need a High-Quality Surface Finish

If you’re trying to fabricate plastic prototypes solely to visualize concepts or ideas, you should consider CNC machining. It offers a high-quality surface finish and doesn’t leave layer marks common in the 3D printing process.

Scenario No 3: You Want to Work with a Special Plastic Material

Plastics and polymers like PVC, PEI, POM, and PEEK are almost impossible to 3D print. A CNC machine is compatible with these plastics and more. A machinist will have no problem creating a CNC plastic prototype design, provided that you have blocks of the plastic material.

Scenario No 4: You Need an Adaptable and Fast Machining Method

Are you looking to create functional plastic prototypes that you can put through testing to troubleshoot design flaws? Because CNC machines rely on 3D CAD models and computer instructions to produce machined plastic prototypes, you can quickly change designs and perform new tests on them.

Some Alternative Methods for Producing Plastic Prototypes

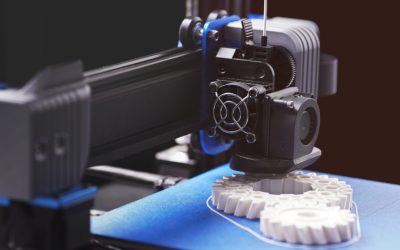

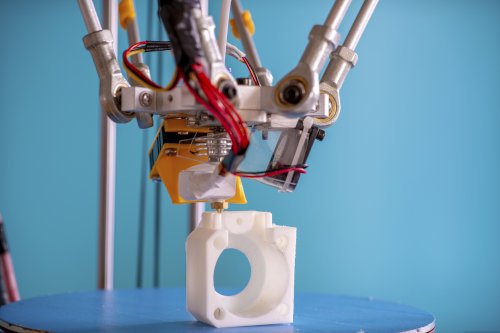

Method #1: 3D Printing

3D printing, also known as additive manufacturing, originated in the 1980s as a tool for rapid prototyping. It encompasses a handful of different technologies- Fused Deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS) — all of which involve adding plastic materials in layers to build plastic parts.

Both 3D printing and CNC machining processes rely on 3D digital models to create parts. However, there is less material wastage in 3D printing than in CNC machining.

Additionally, 3D printing eliminates the need for tool production and allows for the creation of complex geometries. This technology is compatible with thermoplastics like ABS, nylon, PLA, and ULTEM.

Method #2: Injection Molding

Injection molding is another ideal method for quickly producing plastic prototype parts. The process starts with the creation of an aluminum or steel mold with a runner system — a channel that allows molten plastic to flow to the cavity of the mold. The desired plastic prototype shape is formed when molten plastic materials are injected into the mold, allowed to cool and solidify.

Using injection molding ensures that the prototypes hardly require any additional work or surface treatment after production. Plastic injection molding also offers enhanced strength since it is possible to use fillers in the injection molds. What’s more? This plastic prototyping method is cost-effective and can be used for fabricating complex designs.

Method #3: Vacuum Casting

Vacuum casting, also called polyurethane or urethane casting, is a technique for creating high-quality plastic prototypes. The process uses silicone molds and pourable casting resins to make copies of master patterns. You can use these plastic copies to visualize ideas (alpha prototypes) or troubleshoot design flaws (beta prototypes).

Vacuum cast parts exhibit physical qualities and surface finishes that are comparable to injection molded prototypes. The vacuum casting process is also versatile since urethanes (or polyurethanes) of different types can be molded to create specified hardness and desired surface textures.

How to Decide on the Best Method for Your Prototype

CNC machining, 3D printing, injection molding, and vacuum casting have features and advantages that make them suitable for different scenarios.

For example, if you’re looking to work with a difficult plastic material or create complex prototypes with improved structural integrity, CNC machining is your best option. While injection molding also offers improved structural integrity and good mechanical properties, it is better suited for large-scale prototyping or production. This is due to the high-cost associated with making aluminum or steel molds.

A silicone mold in the vacuum casting process can create at most 25 parts; hence, the process is suitable for small production runs. Nevertheless, vacuum cast plastic prototypes usually have great surface finishes and are perfect for the visual representation of design concepts.

Like the vacuum casting process, 3D printing should also be used for small production runs. However, with 3D printing, you can have your prototypes ready in a matter of hours, whereas vacuum casting can have a turnaround time of up to 5 days.

Gensun Precision Machining is a leading precision manufacturing company located in China. Tell us about your prototyping project today, and let us help you determine a suitable prototyping method. Our highly-trained engineers will work with you to create high-quality prototypes using state-of-the-art CNC machining, 3D printing, injection molding, and vacuum casting technologies.