There is significant demand for machined components in the aerospace industry. Did you know that the Boeing 747 comprises over six million parts? Manufacturers need cutting-edge practices and technologies to make components from various engineering materials.

CNC machining is among the most widely used manufacturing methods in the aerospace industry. While it’s likely that you know at least something about it, here are eight things you might not be aware of when it comes to CNC machining aerospace parts.

#1 Lightweight Metals are Crucial to Aircraft Performance

Aluminum and titanium are the most used metals in aircraft due to their high strength. With that in mind, you may be wondering why these materials are more commonly used than steel — after all; it is stronger and cheaper than aluminum and on par with titanium in terms of strength.

It all boils down to these metals being more lightweight than steel.

Titanium is as strong as steel but 45% lighter, while aluminum is about 33% lighter. These lightweight metals are helping to increase the fuel economy and overall efficiency of aircraft. But here’s the problem: they are often tough to machine manually.

CNC machinery boasts compatibility with a wide range of materials and is heavily relied on to fabricate them.

#2 CNC Rapid Prototyping is Vital to Aerospace R&D

R&D is an essential function in the aerospace industry, and CNC machining is at the forefront of the process. Because CNC machines rely on 3D CAD models and computer instructions to create parts, aerospace engineers can rapidly create new prototype designs, test them, and, if needed, edit them.

CNC rapid prototyping helps aerospace companies minimize costs and expenses since it eliminates the need to invest in tooling. More importantly, it helps aerospace companies meet regulatory requirements, such as ISO 9001:2015 and AS9001 standards.

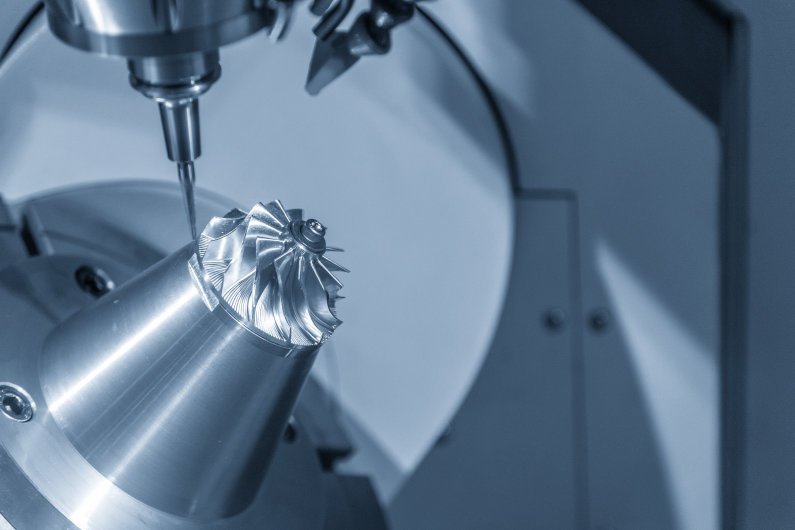

#3 5-Axis CNC Machines Help Fabricate Complex Designs

Aerospace part designs are increasingly complex. For example, NASA’s Orion bulkhead — the part that keeps the crew safe during their journey — is domed near the heat shield and features pockets normal to its surface. Also, aircraft landing gears and fuselage sections are enormous, featuring tiny details and requiring extremely tight machining tolerances.

5-axis CNC milling machines are used to machine these complex parts. They can achieve reaches and angles that might be impossible using 3- or 4-axis machines.

#4 AI-assisted CNC Machinery is Moving Part Production into the Future

Modern-day CNC machines used in the aerospace industry now feature Artificial Intelligence (AI) and Machine Learning software. This allows aerospace companies to see accurate production metrics and achieve aerospace part production goals. This technology is also improving the quality and consistency of machined aerospace parts.

#5 High-Quality Materials Take Aerospace CNC Machining to the Next Level

Using top-quality materials is crucial for aerospace parts to endure extreme conditions like temperature changes, high pressures, and immense forces. These materials include aluminum alloys, titanium alloys, stainless steel, and carbon fiber composites with exceptional properties such as heat resistance, corrosion resistance, and high strength-to-weight ratios ideal for aerospace applications.

CNC machining plays a critical role in processing these advanced materials with accuracy and efficiency to meet the strict requirements of the aerospace industry. Therefore selecting premium materials through stringent quality control measures positively impacts the end product’s overall quality.

#6 CNC Machining Reduces Aerospace Manufacturing Costs

CNC machining helps reduce manufacturing costs for aerospace products by minimizing waste while streamlining production processes. CNC machines can produce complex parts faster than traditional methods without compromising precision.

This precision boosts productivity while lowering labor costs resulting from shorter production cycles. This ability to make high-precision parts relatively quickly is a significant factor in reducing overall manufacturing costs.

The short time required for producing highly accurate parts significantly decreases manufacturing expenses since optimizing material usage minimizes waste leading to sustainable yet cost-effective manufacturing processes contributing towards cost management — vital factors within this industry.

#7 Quality Control is Essential in Aerospace CNC Machining

Maintenance and quality control are critical aspects of aerospace CNC machining. Regular maintenance of CNC machines ensures optimal performance, extends lifespan, and prevents unexpected downtime. By performing routine inspections, calibrations, and cleaning, manufacturers can maintain the accuracy and efficiency of their CNC machines.

Quality control is equally vital in aerospace CNC machining to guarantee that every part meets the required specifications and tolerances. Manufacturers can identify and correct errors by implementing rigorous inspection protocols before they reach the assembly stage.

Advanced techniques like coordinate measuring machines (CMM), laser scanning, and computer vision systems are often used to ensure the accuracy of the machined parts.

#8 Trends Shaping the Future of CNC Machining in Aerospace

Technology is continuing to evolve and innovate at an incredibly rapid pace. Manufacturers have to stay on top of these trends to compete. Several vital trends will likely drive the future of CNC machining in the aerospace industry:

Additive manufacturing: Integrating additive manufacturing (3D printing) with traditional CNC machining will enable the production of complex parts with unique geometries that were previously impossible or too costly to manufacture.

Smart manufacturing: The adoption of Industry 4.0 technologies, such as IoT devices, will allow for real-time monitoring, data collection, and analysis in CNC machining processes. This will enable manufacturers to optimize operations, improve quality control, and reduce waste.

Digital Twins: Creating a digital replica of a physical CNC machine to analyze and optimize its performance is another technology gaining traction. This process can facilitate more efficient machine setups, preventive maintenance, and remote troubleshooting.

These trends will continue to shape the evolution of CNC machining in the aerospace industry, driving innovation and efficiency in the future.

Nothing is as Important as Precision in Aerospace Parts Machining

Like companies in other industries, aerospace companies rely on many third-party manufacturers for different parts. These parts usually require tight tolerances and must correctly mate with parts created in other machine shops. As such, there is no room for geometrical errors during manufacture.

Through precision CNC machining, aerospace companies can create precise parts exactly to specification, achieving tolerances as small as 4μm. At Gensun Precision Machining, we’re experts in precision manufacturing.

This is because we offer custom CNC machining services of the highest quality. We have state-of-the-art CNC machining equipment and experienced engineers, and our production facilities are ISO 9001:2015 certified.