Have you recently reached out to a CNC machining service provider to inquire about their services, or did you stumble upon a CNC machining services page? If so, you must have read something along the lines of “Our CNC machines offer high accuracy and precision and can meet tight tolerance requirements.”

While it’s true that computer numerical controlled (CNC) machines offer these advantages and more, many CNC machine shops overuse the terms “accuracy,” “precision,” and “tolerance” without spelling it out to their customers.

This article will get down to the nitty-gritty of CNC milling machine accuracy, precision, and tolerance. By the end of this read, you’ll be able to confidently discuss your manufacturing project with any manufacturer without feeling overwhelmed by the terms they use to describe their services.

What is the Difference Between Accuracy and Precision?

Accuracy describes the proximity (or closeness) of a measurement to the true value, while precision is the capability of a measurement system to return the same measure repeatedly.

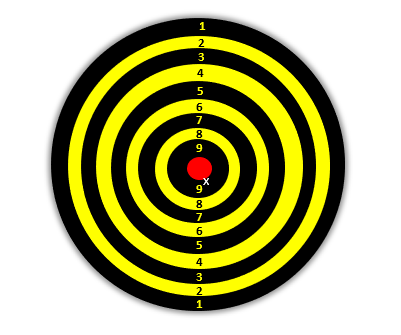

A good way to understand the difference between these terms is to imagine you’re attempting to hit the bullseye in a target practice chart. Accuracy would mean how close your shot is to the center of the chart (the part colored red in Figure 1). Let’s assume your first shot hits the point denoted by “x” in Figure 1. It means you would score 9 points out of a possible 10. We could say your shot was 90% accurate.

Figure 1. Target Practice Chart (High Accuracy)

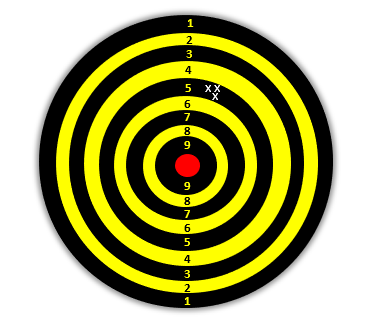

Unhappy by your 90% accuracy, you decide to have a go at it again. But you did worse by hitting the points marked “x” (in Figure 2) three times consecutively. Thus, we could say you were less accurate (50% accuracy) but more precise with your shots. Precision simply means the repeatability of your measurement system.

Figure 2. Target Practice Chart (Low Accuracy-High Precision)

So let’s say you’re looking to make a 100 mm x 50 mm x 10 mm cavity in a metal workpiece. A highly accurate CNC machining service means the CNC cutting tools will cut this metal piece exactly to your specification and without errors. In contrast, a highly precise(or repeatable) CNC machine will create this exact same cut for, say, 100 units of the workpiece.

Now that you understand what gives precision manufacturing its name, let’s talk about tolerances.

What are Tolerances?

Tolerance is the amount of allowable deviation in the dimension of a part. It is typically expressed as “±” (pronounced “plus or minus”) and accompanied by a value, for example, ±0.05 mm.

Tolerance is so important that a slight mistake can hinder the functionality of your design. For instance, let’s say you reach out to another manufacturer to create a cylindrical rod that mates the 10 ±0.05 mm diameter hole. If this manufacturer can meet a tolerance of ±0.07 mm, then you can expect your rod dimension to vary between 9.93 mm and 10.07 mm.

Unfortunately, this rod dimension’s lower and upper limits will make your rod and hole parts functionally useless or incompatible. Can you see why it’s absolutely important to define your tolerances with every CNC machine shop?

How Well Does CNC Machining Perform?

CNC machining is one of the most popular manufacturing processes today. And this is primarily due to its high accuracy, precision, and tight tolerance range. In fact, with CNC machining, you can accurately create over 1000 units of identical parts while achieving tolerances as small as ±0.04 mm.

However, all these advantages will only be felt if you work with a top-tier CNC machine shop.

Gensun Precision Machining is a leading provider of high-quality CNC machining services across the globe. We’ve been in business for nearly two decades, creating accurate and precise parts for our customers while meeting their tolerance requirements.

Learn more about our precision CNC machining services.